Cartamundi’s East Longmeadow Plant Is Open for Business

Game On

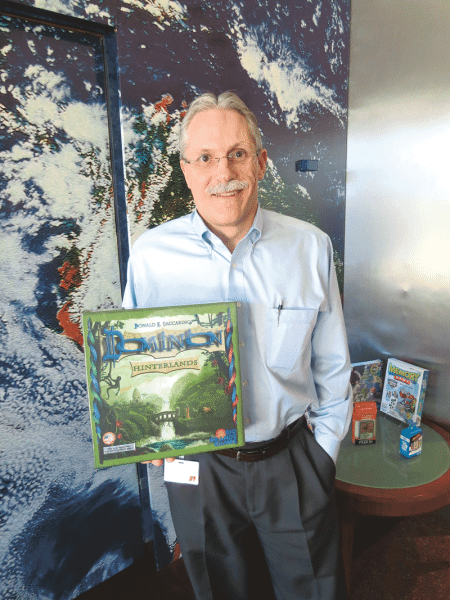

Bob Adams says one of the unofficial goals at Cartamundi East Longmeadow is to diversify the list of products made there, and thus the showroom in the front lobby as well.

Since Cartamundi acquired the Hasbro plant in East Longmeadow in 2015, the two companies have been closely linked — in news accounts and everywhere else. And that’s understandable, because the toy and game developer is easily the biggest customer for the East Longmeadow plant. But those managing that facility are working hard to make it clear that this facility can do much more than make games for Hasbro.

Bob Adams acknowledged there are many benefits to the recent announcement that Play-Doh — that curious, multi-colored molding compound that has been part of American culture for more than 60 years — will again be made at the massive manufacturing facility in East Longmeadow now owned and operated by Cartamundi.

They begin with what will likely be, by most estimates, an additional 20 jobs at the plant, which previously had the household names Milton Bradley and Hasbro (producers of Play-Doh) on the sign out front. But there is more to this than employment opportunities, said Adams, manager of sales and new business development for Cartamundi East Longmeadow LLC, who has worked at that plant, off and mostly on, for nearly 40 years.

Indeed, there is the publicity that came with the announcement, obviously — the Wall Street Journal and a host of other media outlets covered the story — and also the fact that the plant, the largest games-manufacturing facility in North America, now has what amounts to another huge identifying product, with the board game Monopoly long being the other.

“That brings visibility to this plant,” he said of the Play-Doh contract, which extends over several years. “When I talk to people about having Cartamundi East Longmeadow do some business with them, they have a much better chance of knowing who Cartamundi East Longmeadow is.”

About the only thing this announcement doesn’t do — and this is not exactly an insignificant development, either — is let the world know that Cartamundi, and this plant, are about much more than Hasbro and, well, fun and games.

Indeed, while Hasbro is easily the most dominant client, and games of all kinds serve as the primary stock and trade for Belgium-based Cartamundi, the company can do much more — and it wants to get this message out.

“We’re not only still making many of Hasbro’s products, but we’re out soliciting business from other customers,” he said, explaining that Cartamundi is, for the most part, a contract manufacturer and generally doesn’t put its own name on what rolls off the assembly line. “And while the customer base is centered on games, because that’s our specialty, we’re also looking to use our core competencies to support other businesses.”

With that, Adams got up from his chair, reached to a high shelf on the credenza behind him, and grabbed a box, which, if it wasn’t occupying space in his office, would otherwise be holding an assortment of Lindt chocolates.

We want to be less reliant on Hasbro and leverage our competencies to build our contract business. And to do that, we’re developing our own sales organization and building our own identity in this region.”

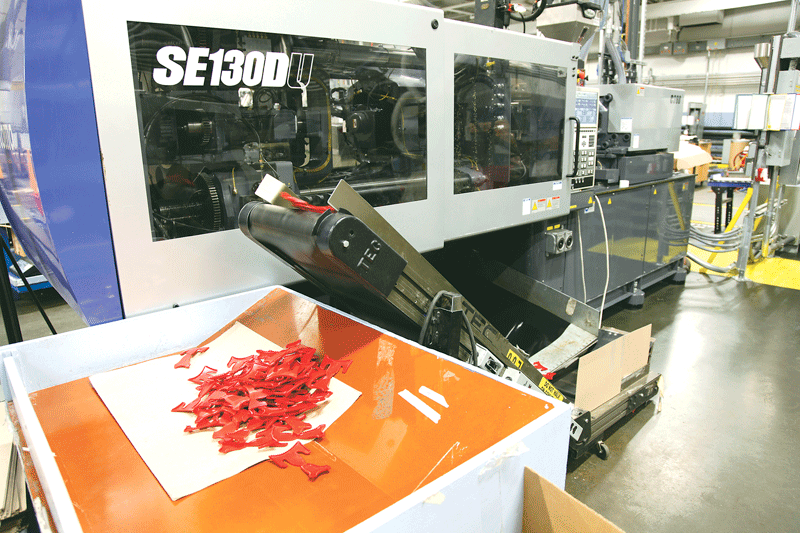

“This is just one of the things we can do here — we started last June, and last year we made more than 1.7 million boxes for Lindt,” he said, holding the gold-toned item aloft, adding that the company has, for example, injection-molding machines with additional capacity, and can also take on thermoforming work, box making, die cutting, assembly, and much more.

“We want to get the word out that we’re open for business,” he went on, adding that, in his new capacity, he is essentially leading the efforts to bring new business to the plant — the immediate goal is to increase non-Hasbro contract manufacturing by 30% — and diversify the list of products manufactured there.

Jeffrey Lombard, CEO of both the East Longmeadow facility and a sister facility in Waterford, Ireland, also purchased by Cartamundi, told BusinessWest that Hasbro projects (not including Play-Doh, which will start rolling off the lines during the first half of 2018) amount to roughly 90% of the production in East Longmeadow.

He would like to see that volume of work rise still higher, but the percentage rate go down as the plant takes on other work, such as games for other developers, as well as Lindt boxes and similar projects.

“We want to be less reliant on Hasbro and leverage our competencies to build our contract business,” said Lombard, who held a succession of operations positions for Hasbro and was serving as senior vice president of Domestic Manufacturing when it sold the East Longmeadow plant. “And to do that, we’re developing our own sales organization and building our own identity in this region.”

While the company is mostly ready to do that, it will be challenged to greatly increase capacity by the same issue facing virtually every other manufacturer in this region — finding skilled help.

“Short-term, like every other manufacturer in the Northeast, and probably in the U.S., we’re not limited by equipment capacity, per se,” he explained. “The problem in this region is the hiring of skilled employees; that’s the biggest inhibitor to short-term growth.”

Jeffrey Lombard says Cartamundi East Longmeadow has the potential to increase capacity by 30%, but is challenged in that assignment by the task of finding qualified help.

For this issue, BusinessWest talked at length with Adams and Lombard about what’s happening at Cartamundi’s East Longmeadow plant today — and what could happen there in the years to come if all goes according to plan. You might sum it up neatly and effectively by simply saying ‘game on’ — although, as noted, that’s certainly not the whole story.

Pieces to the Puzzle

Adams and Lombard can easily trace the history of the East Longmeadow facility, because they’ve both witnessed most of it first-hand.

Adams was just out of high school in 1978 when he applied for a job at the plant, which Milton Bradley opened roughly a decade earlier, and landed a position in the warehouse.

He probably couldn’t have known then he would still be coming to work there — except for a stint in Rhode Island and a subsequent brief retirement and work as a consultant to game manufacturers, including Hasbro — nearly 40 years later. But, then again, maybe he did.

“It was a great place to work,” he explained. “It was a very well-run company, and family-oriented. My mother worked here, as did my aunt and my uncle. People came here, and they stayed here.”

Over those ensuing decades, he put a number of titles on his business card and wore a number of hats. Starting in 1985, for example, he moved into an office job as a production planner. He then moved on to work in industrial engineering, delving into everything from efforts to improve efficiency to early — and in many ways groundbreaking — initiatives in ergonomics.

Later, he became new-business coordinator, working in tandem with development teams that had been based in East Longmeadow, were later moved to Hasbro’s facilities in Beverly, and then moved back. Subsequently, he went into project management and then became leader of Hasbro’s boys’ toys project-management organization in Pawtucket, R.I., essentially to bring the best practices of the East Longmeadow operation to that unit.

After doing that for three years, and amid changes to those operations, he decided to take a retirement package at age 52 and do consulting work, primarily for Hasbro, and did that until Cartamundi bought the East Longmeadow plant.

Summing things up, Adams said he saw long ago what Cartamundi saw when it researched and ultimately decided to acquire the East Longmeadow plant in 2015 — highly skilled workers and an operation that could do so much more than manufacture some of the games that bore the Hasbro name.

“When Cartamundi bought the facility, I was very happy for the people who worked here,” he told BusinessWest, “because I knew there were tons of opportunities to grow the business and bring back manufacturing expertise to this area; there were a lot of positives.

“This was a really good fit for both sides — with Hasbro wanting to be out of the manufacturing business, and Cartamundi wanting to be in the manufacturing business,” Adams went on. “This was an opportunity for both companies to grow their business the way they wanted to grow their business, and so they made it happen.”

His current title, director of sales and new business development, is one that no one has ever had at the plant before (again, it was always an in-house manufacturer for Hasbro, and thus sales were not part of the equation). And, as noted earlier, these new assignments come down to attracting both more work in games — and there is plenty of it out there — and work that falls well outside that realm.

Marketing to potential clients through the website 360manufacturingservices.com, Adams said he’s receiving three or four inquiries a day, on average, many of them from small game-development companies looking to outsource manufacturing operations.

With the acquisition of Hasbro’s plants, Cartamundi is now the largest games manufacturer in the world, he went on, and it is well known for its production of playing cards, most of them made at the company’s plant in Texas (cards for specific games, like Monopoly, are also made at the East Longmeadow plant), so it is often a go-to source for companies seeking such services.

But, overall, Cartamundi is looking for new clients with high volumes of work, and has provided quotes on everything from boxes to plastic snow shovels.

“It has to make sense for both of us,” he said of the contract work. “It usually doesn’t make sense for low-volume manufacturing.”

Board Meetings

Without actually saying as much, Adams said Cartamundi’s primary mission at the moment — and his as well — is to broaden and diversify the shelves in the front lobby of the East Longmeadow plant.

There, on display, is a random sampling of what is produced on the factory floor. And at the moment, the shelves are crammed with all kinds of games, from stalwarts like Clue, Scrabble, and Yahtzee to speciality items, such as Star Wars versions of everything from Monopoly to Sorry, and even Operation.

There is expertise and capacity to add new items and greatly diversify what’s on those shelves, said Adams, adding that the two immediate goals are to generate new business from existing clients and add new customers to the portfolio.

“We want to work with existing customers to provide them with exceptional customer service and support so that we can grow our business with those existing customers,” he explained. “We’re also looking to grow our customer base in the main game aisle, meaning new lines of products from other game distributors, and we’re looking for local companies that can take advantage of our core competencies.

“There are a lot of opportunities out there, and that’s why I’m back,” he said, adding that there are many pieces to the puzzle, to use an industry term, when it comes to achieving the plans for growth the company has laid out.

These include everything from marketing — something else that was never really undertaken at the East Longmeadow plant — to raising the company’s profile, in part by making the 360 Manufacturing website much more integrated into the Cartamundi site, to building an infrastructure for new-business development, said Adams, whose hiring was one of the first major steps in this direction.

Other steps have been taken as well, said Lombard, referring to that sales organization he mentioned earlier. They include the hiring of a customer account representative and the planned hiring of a customer project manager to create an even sharper focus on price, customer service, and quality.

“That’s all new; everything we’re doing along these lines is new,” he said, again noting that, as an in-house manufacturer for Hasbro, such matters were not priorities, so there will definitely be a learning curve.

Injection molding, undertaken by machines like this one, is one of many core competencies that Cartamundi East Longmeadow is looking to sell to new customers.

Speaking of learning curves, though, perhaps the biggest challenge facing the company as it pursues those goals is finding enough qualified help.

“We don’t need more equipment to increase our capacity; we need more skilled labor,” said Lombard, adding that, like other manufacturers in the region, Cartamundi will work to make itself and its various career opportunities highly visible.

Long-term, he believes the company has the ability to grow capacity by that 30% goal stated earlier.

“We’re in the process of growing what I call our efficiently flexible capacity, and that’s really a function of getting some skilled employees in the door and trained, and we’re aggressively pursuing that,” he explained, adding that one of the keys to success in such efforts is to build the brand and establish an identity.

“One of things that inhibits us is that people in this region don’t know who Cartamundi is,” he said, adding that, through a variety of steps, including a stronger web presence, he’ll look to stem this identity problem.

The Shape of Things to Come

As every Baby Boomer — and every member of all the subsequent generations, for that matter — can tell you, Play-Doh can be molded into just about anything the user can think of. The only real limit is the imagination.

In many respects, the same is true when it comes to contract manufacturing at Cartamundi’s East Longmeadow facility. It will always be known as the place where memory-inducing game pieces — like Sorry! pawns and Monopoly houses and hotels — are manufactured. And soon, it will again be known for Play-Doh.

But as Adams and Lombard made clear, it can become a resource to make a host of products that are perhaps less famous but no less important to the companies relying on them.

So it’s a whole new game at the landmark plant, one that officials there certainly believe it can win.

George O’Brien can be reached at [email protected]