Series of Key Partnerships Will Help Develop a Rail-car Workforce

On Schedule

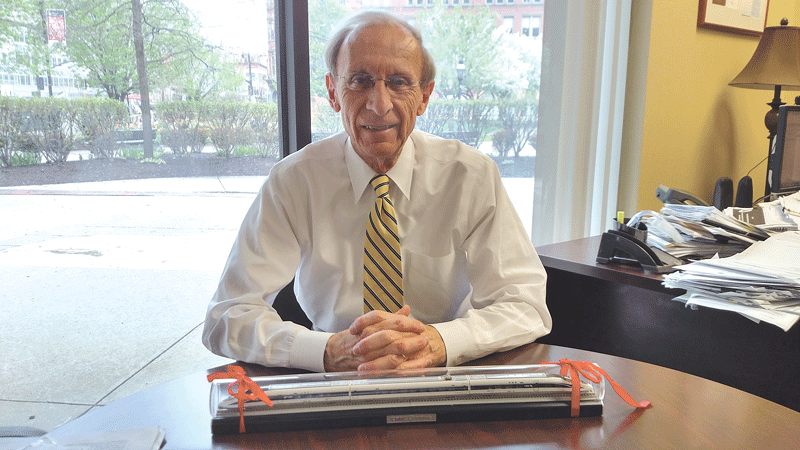

David Cruise says partnerships to raise up a workforce for CRRC MA USA. will benefit the region’s entire manufacturing sector.

When a company from across the globe sets up shop in Springfield, it can’t exactly bring its workforce with it.

“We need 100% new employees,” said Bobby Doyle, senior consultant for CRRC MA USA, the Chinese rail-car manufacturer currently building a $95 million production plant at the former Westinghouse site on Page Boulevard. “We can’t transfer people from China here; it wouldn’t work.”

Among the reasons CRRC — formerly CNR Changchun Railway Vehicles — chose Springfield, however, was optimism that the city and region could supply a workforce to support what will become the company’s North American headquarters. “The capital investment we’re putting in, that’s a big commitment,” he said, “and there’s got to be a long-term labor force.”

That’s why CRRC has forged a number of interlocking partnerships — with the Regional Employment Board (REB) of Hampden County, the local sheet-metal and electrical unions, Roger L. Putnam Vocational Technical Academy, and the engineering departments of area colleges and universities, for starters — to build that workforce.

But local economic-development leaders see potential benefits to these partnerships beyond the CRRC jobs, said David Cruise, the REB’s president and CEO.

“We’ve been working with [Doyle] to identify very specific production positions they will need on the factory floor,” he said. “They’ll need some administrative positions and engineering positions, but at the Regional Employment Board, we’re focusing on how to help them on the factory floor, where the heart of the work is going to get done.”

At the same time, Cruise continued, “we’re also concerned with not just identifying the workforce for CRRC, but with the broader regional metal-fabrication industry as well, hoping other companies benefit from the presence of CRRC in the region. We want to be sure that any sort of workforce training we develop benefits that broader metal-fabrication industry. That’s been our strategy.”

He explained that CRRC could present some spinoff work for other manufacturers and perhaps attract new manufacturing business to the region.

“We certainly want to be a conduit and help with CRRC Massachusetts, but we also shared with them, and they understand the value of, our intent to build training programs and build a delivery system that can respond to all the needs that may develop here in the region.”

Local Flavor

In 2014, CNR Changchun received a $566 million contract to manufacture 284 new subway cars for the Massachusetts Bay Transportation Authority (MBTA — 152 for the Orange Line and 132 for the Red Line.)

Construction at the 40-acre site — including a new, 220,000-square-foot factory building and conversion of the former Westinghouse administration building into CRRC’s administrative, engineering, and research offices — is underway. When it’s fully operational in 2018, the factory will employ 150 production workers with starting salaries of at least $66,000 a year, on top of about 150 construction workers needed to build the new plant. The MBTA cars will be built over a five-year period.

To develop a worker pool with the necessary skills, the REB is working closely with Sheet Metal Workers Local 63 and Electrical Workers Local 7 to develop training programs to be hosted mainly at Putnam after school hours.

“Putnam has some of the latest technology and equipment in the area, and I felt it was really critical to build that relationship between Local 63, Local 7, and Putnam,” Cruise said.

Along with training workers currently in the field for CRRC’s immediate demand, another goal is to attract unemployed and underemployed individuals into the training programs to prepare for a surge in demand as the rail-car plant grows beyond its initial buildout.

“As this facility comes online, the majority of initial-wave workers will be individuals who have experience in sheet-metal and electrical work,” Cruise said. “But as the facility expands and grows, clearly there will be some opportunities for entry-level positions.”

Cruise believes that, indeed, CRRC will be that kind of catalyst.

“We think this assembly facility will lead to the development of contracts with other municipalities and states around the country, with hope that some, if not all, of that work finds its way back to Springfield,” he told BusinessWest. “We’re not building programs just to get to opening day, but that can grow with them — and they can have some assurances that broader training is in place to meet future demand. There will be times when their workforce will be expanding pretty dramatically.”

Doyle agreed. “We’re pursuing two other contracts right now, one in Pennsylvania and one in Los Angeles, and both would be manufactured in Springfield, so Springfield is going to be a very busy location in the next five years,” he said. “We’d like to see the workforce keep doubling if we’re successful.”

Cruise said the after-school programs at Putnam — say, 3 to 9 p.m. — will complement offerings at Local 63’s own training center during the day. “That gives us 12 hours a day, which is exciting for us. It gives us some real bandwidth in terms of not only building great programs, but having some flexibility in scheduling.”

Meanwhile, the REB is working on a similar arrangement with Local 7, developing a curriculum for training programs to meet CRRC’s specific needs. “They’re excited to partner with us. They have a training facility in Chicopee, so we can run the same kind of afternoon program at Putnam, and at the same time utilize Local 7’s training facility during the day should demand dictate.”

The REB will look to competitive state grants to fund these programs. “It’s a challenge to identify funding to do this; unions are not allowed to use their funding for apprenticeship programs.”

That issue aside, Doyle called Putnam a “tremendous resource” and noted that CRRC officials have visited several times already. “We see them as a huge long-term partner.”

Once the initial hiring process is complete, a group of 20 to 30 employees, maybe more, will relocate to China for 10 months to a year to train on light rail cars in that country, learning how to test all the systems in the trains and bringing that technology back to Springfield. A second group of employees will go to China for four months to learn the assembly process. Production of the MBTA cars will begin in Springfield early in 2018.

College Try

CRRC is starting to build other connections as well, working with Western New England University’s College of Engineering to develop talent for the design and research operations at the new plant, and examining similar opportunities with UMass Amherst and Springfield Technical Community College. Meanwhile, FutureWorks, the one-stop career center located in Springfield, will serve as a resource for the hiring process.

“For them to be able to see that these kind of partnerships can be developed quickly — that they’re coordinated, agile, flexible, and can respond to their business demands — to me is adding great value and ensuring this corporation, and the industries that will benefit from it, will have a very bright future, not only here in Massachusetts, but across the country,” Cruise said.

Doyle admitted that, during CRRC’s search for a North American home, Springfield posed some negatives, including one of the highest commercial tax rates in the Commonwealth. But other positive factors outweighed that, including the city’s proximity to two major interstates and a CSX Transportation rail line, and, yes, those aforementioned partnerships, and the enthusiasm of the municipal and economic-development leaders who forged them.

“I’m excited about where we are,” Cruise said. “We’ve worked over time with a lot of different companies and a lot of different partnership arrangements. This is especially exciting because the parties we pulled together do not have an established history of working as partners in this workforce-development space.”

Therefore, he went on, “we are excited about the opportunity this company presents to the city of Springfield and the region and job-creation efforts here in the Valley. Quite honestly, I can’t wait to get started.”

Joseph Bednar can be reached at [email protected]