Thinking Outside the Bridge

By Daniel Holmes and Andrea Lacasse

The new modular, prefabricated truss bridge rests on the existing abutments and is secured to the reconstructed bridge seat.

Photo by Tighe & Bond

The Town of Great Barrington was faced with a substantial challenge: one of its main bridges, the Division Street bridge, connecting two state routes, had to be shut down due to deterioration and safety concerns. This created a significant detour for local traffic as well as upsetting an important truck route, causing congestion in the downtown area. The town acted quickly to find a solution that would not only be cost-effective and work within an expedited schedule, but would benefit the local communities and all who use the bridge.

The town engaged Tighe & Bond to review the Massachusetts Department of Transportation’s (MassDOT) inspection reports for all town-owned bridges crossing the Housatonic River. It soon became clear that the bridge on Division Street over the Housatonic River needed rehabilitation and potentially a complete structure replacement.

The original, 138-foot, single-span, through-truss bridge was constructed in 1950 and carried two 10-foot traffic lanes with no sidewalks or breakdown lanes. The bridge has always been a popular area for hiking, biking, walking, and fishing, as well as an important truck route connecting Route 7 to Route 41, keeping truck traffic out of downtown Great Barrington. In addition, Division Street is an important artery for local traffic and the agricultural community.

With the potential for the bridge to be closed entirely, Tighe & Bond got to work developing cost estimates for varying levels of rehabilitation and/or complete replacement of the bridge to provide the town with the most cost-effective design solutions for the bridge.

In 2019, a town meeting voted to appropriate funding to replace the bridge. Soon after, Tighe & Bond began data collection and preliminary engineering as well as a bridge-replacement alternatives analysis. However, while the replacement bridge was being designed, the due diligence of a MassDOT special member inspection and subsequent load rating report found that three structural elements were rated at zero capacity, and the bridge was closed immediately. This created a five-mile detour, causing additional congestion for Great Barrington’s downtown area.

With the bridge closed, the town requested Tighe & Bond refocus on emergency repairs to reopen the bridge as quickly as possible. Tighe & Bond and the town reached out to MassDOT to switch gears and begin the design of emergency repairs for the three zero-rated elements to reopen the bridge to local traffic as quickly and safely as possible.

“To avoid a prolonged closure of the Division Street bridge, Tighe & Bond proposed to the town a temporary superstructure replacement, which would allow the critical crossing to reopen until the permanent bridge replacement was installed.”

Through further examination of the inspection and load rating results, MassDOT indicated that the bridge deterioration had advanced to a point where rehabilitation would not be possible, and a complete replacement would be required. MassDOT then informed the town it would be able to get the bridge on the State Transportation Improvement Plan and the state would replace the bridge, but it would effectively delay the reopening of the new bridge for several years until the necessary funds could be allocated, design completed, and construction executed. The estimated reopening date was sometime in 2027.

To avoid a prolonged closure of the Division Street bridge, Tighe & Bond proposed to the town a temporary superstructure replacement, which would allow the critical crossing to reopen until the permanent bridge replacement was installed.

The town reallocated funds from the town-funded bridge replacement into an accelerated reopening of the bridge with a temporary superstructure replacement. Tighe & Bond evaluated the existing abutments for reuse to determine if they were sufficient to continue to support the same load. The team of engineers determined that the existing abutments could support the same load and could be reused for the project.

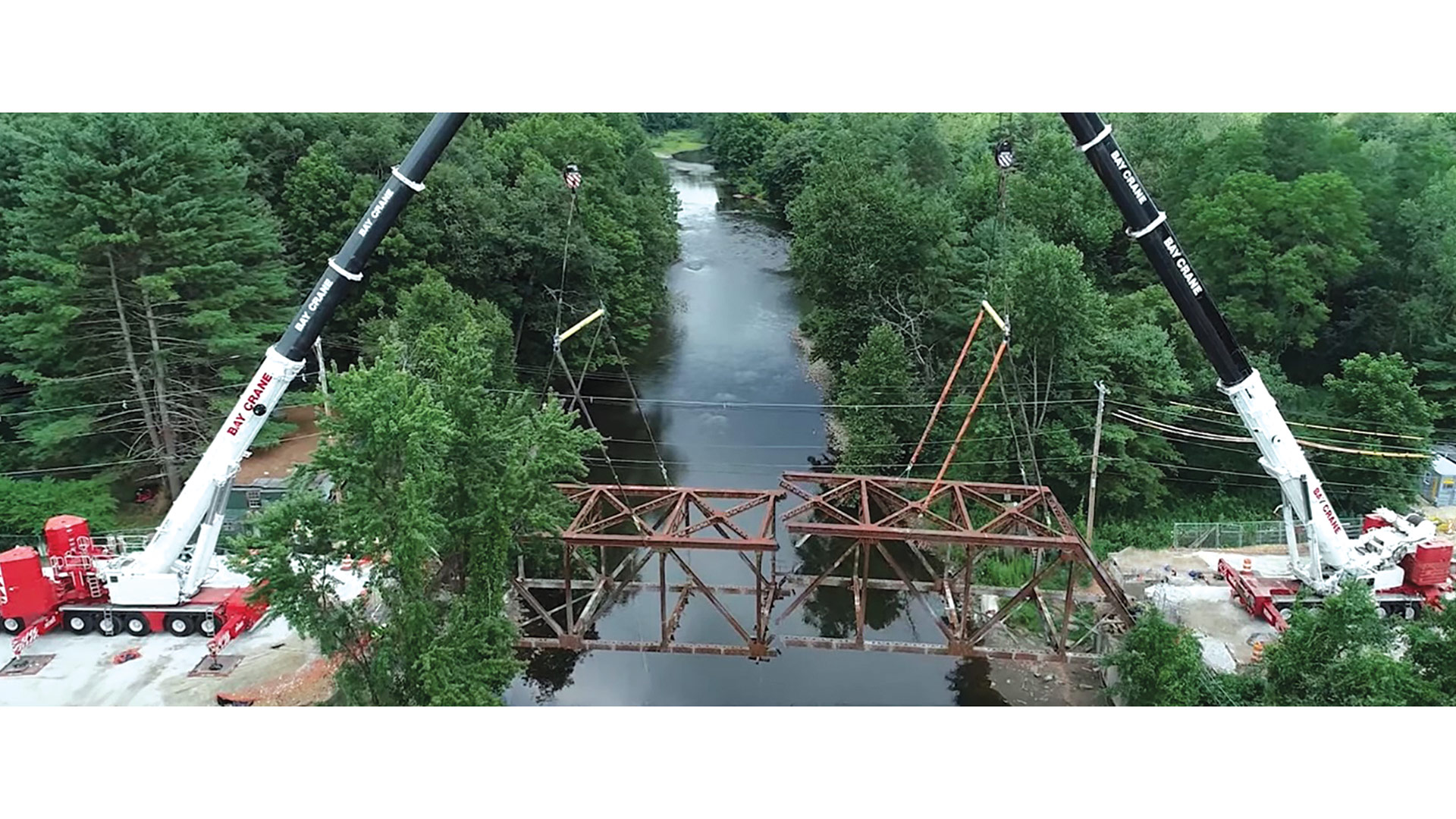

This aerial view shows the old truss being removed by cranes.

Photo by Tighe & Bond

To accommodate the town’s request of eliminating the previous load restriction while reusing the existing abutments, Tighe & Bond engineers proposed a single-lane modular truss with a cantilevered pedestrian walkway. The single-lane traffic could be controlled with new traffic signals, effectively reopening traffic flow along this important corridor while the town awaited the permanent bridge replacement.

Logistical and Environmental Challenges

With consensus on the design approach, time was of the essence, and the design team put the agreed-upon plan into action immediately. While Tighe & Bond mobilized the design team, the town continued its public outreach effort, keeping the local community informed through Select Board meetings, social-media posts, and press releases. Tighe & Bond participated in several town meetings to provide answers to technical questions and support the town’s effort.

There were a few unique challenges the team had to work around in order to make this project a success. For one thing, the permits would need to consider the potential impacts the superstructure replacement would have on rare and endangered species. The permitting process included a proactive conversation with the Natural Heritage and Endangered Species Program to discuss the potential impacts construction methods could have on three identified endangered species — creeper mussels, brook snaketail dragonflies, and longnose suckers — as well as potential actions that could be taken to minimize impacts.

Tighe & Bond adapted the solution of keeping all construction work out of the limits of the Housatonic riverbank, removing potential impacts to the river habitat below. Although this approach created challenges during construction, it reduced the overall project schedule by one year.

Another design challenge included working around energized overhead power lines encroaching onto the job site. Tighe & Bond coordinated with National Grid to relocate the power lines to provide contractors with space to execute their demolition and erection plans while adhering to OSHA guidelines, providing at least 10 feet of clearance.

“They were able to quickly pivot design plans to meet the needs of our community in a way that allowed us to ensure safe traffic flow, save the town money, and not disrupt habitats around the Housatonic River.”

Once the design phase was complete, the demolition and construction of the replacement bridge required all hands on deck in order to reopen the bridge before the winter of 2022. Every member of the project team was integral to the success of this project. This included the town of Great Barrington, Tighe & Bond (engineer of record), and Rifenburg Contracting Corp. (contractor), along with subcontractors Seifert Associates (construction engineer), Atlantic Coast Dismantling (demolition), Acrow (truss manufacturer), and Lapinski Electric (traffic signal).

Innovative demolition techniques were put into action to avoid work within the riverbank and the energized power lines encroaching on the job site. Using cranes on either approach, Seifert worked with Atlantic Dismantling to split the truss into two pieces using thermal lancing rods, then lifting the two halves and swinging them to a temporary location outside the riverbank for disassembly before being trucked off-site. This method resulted in the removal of the bridge without impacting the endangered species’ habitats in any way.

With the existing bridge removed, it was time to install the new modular, prefabricated truss bridge. Reuse of the existing abutments not only reduced cost and time, but also kept to the team’s commitment to protect the local endangered-species habitat. The abutments were modified to receive the new truss.

The new modular bridge was then constructed on the east side of the project area and ‘launched’ toward the west abutment as it was counterweighted to allow the bridge to extend approximately halfway across the span. Once safely at rest, the crane positioned behind the west abutment connected to the end of the bridge and lifted it while an excavator on the east aided in the remaining launch by pushing the bridge the remainder of the span, where it finally rested on both abutments and was secured to the reconstructed bridge seat.

With substantial efforts by all parties, the construction project was completed on time and on budget with no change orders issued.

Future Opportunities

The collaborative partnership between the project team resulted in Division Street being open to traffic once again. In addition, the new modular, prefabricated truss bridge will remain a resource to Great Barrington going forward. Not only can the town use the new truss bridge for Division Street, once the bridge is permanently replaced by MassDOT, the town can either sell the truss bridge to help fund future projects or reuse the bridge for any future needs that may arise, saving time and money.

“Tighe & Bond and the entire team did a great job with this project. They were able to quickly pivot design plans to meet the needs of our community in a way that allowed us to ensure safe traffic flow, save the town money, and not disrupt habitats around the Housatonic River,” Great Barrington Town Manager Mark Pruhenski said. “We look forward to driving over the bridge every day.”

Daniel Holmes is a senior project manager, and Andrea Lacasse is a structural engineer, at Tighe & Bond. Contributing to this article are Emily White, proposal and content management specialist, and Regina Sibilia, marketing and communications specialist.