MachineMetrics is Producing Results for Customers

By Any Measure

Bill Bither, co-founder of Machine Metrics, on the shop floor at Valley Steel Stamp in Greenfield.

Western Massachusetts has a rich history of entrepreneurship that dates back more than 300 years. Springfield, but also the entire region surrounding it, has been home to a number of innovations — and also companies that manufactured those products. Now, a new and very strong wave of entrepreneurial energy is sweeping across the region, and it is taking many forms, especially a slew of startups and next-stage companies trying to develop the proverbial next big thing. Over the next several months, BusinessWest will profile some of these emerging companies to provide its readership with deep insight into some of many positive developments taking shape here. We start with a Northampton-based venture that has brought to the market a software system that measures manufacturing productivity. The president of a Greenfield-based company now using it was direct in his assessment: “It’s a game-changer.”

They call it “being in the green.”

And that short, simple phrase has become a huge part of the lexicon at Valley Steel Stamp (VSS) in Greenfield — and with good reason.

To explain why, Rico Traversa, the company’s operating manager and a manufacturing engineer, took BusinessWest to the so-called war room, what those at this rapidly growing precision manufacturer of parts for the aerospace industry, major arms makers, and other customer groups call the operations center, located just off the shop floor.

There, on one wall, are two large, digital display boards, or dashboards, as they’re called, an integral part of a performance-monitoring system created and installed by Northampton-based MachineMetrics. One dashboard shows 11 circular graphs, or rings, that essentially chart the execution of each machine tied into the system and each production shift — in real time.

It is 2:05 p.m., so the second shift has just started, and therefore all but one of the rings are green, meaning the machines are operating at or above the desired performance levels. One is orange, which means it is operating slightly below that level. If one should happen to turn red, it means what that color usually means — trouble.

But because of the dashboards and other elements of this system, that trouble can be identified, and dealt with, much sooner and more effectively than previously possible, said Steve Capshaw, president of VSS, who spoke about Machine Metrics with an enthusiasm that was clearly evident.

“This is an absolute game changer for us,” he said, adding quickly that it could also be considered one for the precision-manufacturing industry as well, a sector that has for years been starving not only for big data, but, more importantly, a way to effectively digest it.

Capshaw said the MachineMetrics system has yielded a roughly 20% increase in efficiency since it was implemented about a year ago, a huge number in this industry. When asked to qualify and quantify what that meant, he said this improvement will not only accelerate the company’s already-ambitious growth projections — Capshaw said VSS has tripled in size, from $3 million to $10 million over the past five years, and expects to reach $20 million in another five years — but enable it to navigate this industry’s most pressing, and perplexing, problem, a deep talent shortage, far more effectively.

“If you can put out 20% more parts per year, that directly lands on your bottom line,” he explained. “MachineMetrics will allow us to negate roughly $2 million in capital expenditures in the next five years as we double the size of the business. If you’re less efficient, you have to buy more machines.”

This simple arithmetic means that Bill Bither, Eric Fogg, and others involved with MachineMetrics seemingly have the right product at absolutely the right time.

Eric Fogg says the MachineMetrics system analyzes performance in real time and sends alerts to clients when production falls behind.

Indeed, with successful stories being scripted at VSS and a handful of other clients, the company is poised to greatly expand its customer base and geographic reach. Fogg, whose business card declares that he is vice president and “chief evangelist” of this venture, was readying for a trip to Colorado when he spoke with BusinessWest, and was expecting to advance and perhaps close a significant deal.

Bither said the company recently closed on a round of venture-capital funding that exceeded $1 million. That infusion will be used to help scale up the venture and “prove out the sales model,” thus broadening the company’s customer portfolio to manufacturers of all sizes.

“Right now, it’s about product development and making sure we have the capability of selling this to many types of manufacturers that have different types of needs,” he said, adding that, while the company has shown it can serve a relatively small shop like VSS, it must shape the model to accommodate corporations with billions in sales and thousands of machines.

Parts of the Whole

As he talked about the MachineMetrics product, Capshaw noted that the precision-machining industry generally runs at least five years behind other sectors when it comes to advances in IT and, especially, the interpretation of big data.

That’s primarily because the equipment being used on shop floors today is quite complex, and IT is generally applied to those machines long after they are up and running.

“We can generate and consolidate vast sums of data,” he explained. “That’s great, unless you can’t do anything with it, which is where this industry was until only a few years ago.”

What was needed, he went on, was a standard language by which the controls of machine tools could export common information for which applications could be written.

The machine-tool industry eventually came together to create that language, called MTConnect, said Capshaw, adding that what has followed could best be described as attempts to harness that language. Overall, advances have come slowly and marginally — until MachineMetrics.

“Five years ago, we went to the International Machine Tool Show in Chicago, a huge show that comes every two years, and looked at machine-monitoring software,” he explained. “There was basically one company there that did it; they didn’t use the MTConnect standard, and the system was clunky. It’s like, if you were looking for a computer today, you knew what you wanted, you went to a store, and all they had was a Commodore 64 or Apple IIe.

“So we decided to wait a few years,” he said, adding that the next Machine Tool Show featured perhaps 20 vendors with monitoring software, with most of the products still lacking in one or more ways.

Machine Metrics wasn’t one of those companies, because it hadn’t yet been incorporated, but the seeds were being sown for a system that could potentially change the landscape.

The principals would bring to the table experience in entrepreneurship, software development, problem solving, and precision machining. Indeed, by that time, both Bither and Fogg could already be considered serial entrepreneurs.

Bither, a member of BusinessWest’s first 40 Under 40 class in 2007, founded the enterprise software company Atalasoft, which he later sold to Kofax, now Lexmark. Prior to that entrepreneurial episode, he worked in aerospace engineering — he was a design engineer at Hamilton Sundstrand for several years — and knew Capshaw from his work in that field.

Fogg, meanwhile, began his career in a machine shop in his hometown of Brattleboro, Vt. He started out packing boxes and washing parts, and eventually worked his way up to programmer.

He later started his own machine shop, Greentech Engineering, in Holyoke, which, as that name suggests, specialized in the engineering and prototyping of green-technology products, including mounts for solar panels and prototype wind turbines.

To make ends meet, he took on some aerospace work at night, he said, adding that the recession that started in 2008 put a rather large dent in both aspects of his business, prompting a shift into consulting work that focused on his strengths in precision manufacturing and ‘green’ product development.

Fogg said he met Bither at a Valley Venture Mentors meeting soon after he sold Altalasoft, and the two began looking at challenges they could undertake together. Their knowledge of the precision-machining field made them keenly aware that there would be a huge opportunity awaiting those who could develop software that could effectively monitor and record the performance of machines and people, and they set out to create it.

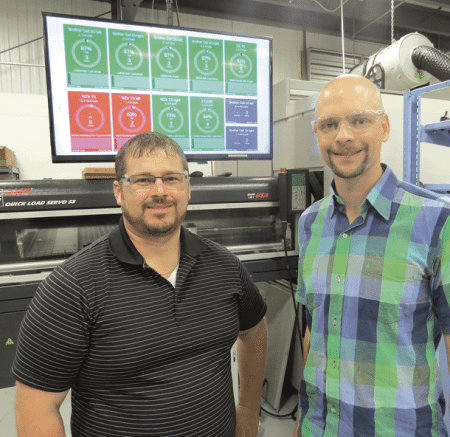

Rico Traversa, operating manager at Valley Steel Stamp (left), and MachineMetrics co-founder Bill Bither stand near one of the dashboards on the VSS shop floor.

Together, they brought MachineMetrics to the market using VSS as a pilot company — one that has seen results far exceed expectations.

Form and Function

As he discussed what the MachineMetrics product means to manufacturers, Fogg related what sounded like a not-so-hypothetical situation involving that machine shop he worked for years ago.

“My boss would come down and say, ‘I need to ship 300 of these parts, and we’re already a week late,’” he recalled. “I would say, ‘well, there’s only 60 of them complete.’ He would get angry and say, ‘what went wrong?’

“The thing about manufacturing, and probably a lot of other industries, is that I could have given him the top 10 reasons why that job was behind, and it wouldn’t have constituted 5% about why it was actually behind,” Fogg went on. “There’s so much stuff that can happen, so many discrete things that can go on, that there’s really no way you can sit down with your boss and explain why a job is behind. So I would come up with some cop-out answers like ‘we’re having some trouble with second shift’ or ‘maybe there’s trouble with materials,’ and he would nod his head and go upstairs to call a soon-to-be-angry customer and eat crow.”

Machine Metrics was designed to make such discussions a thing of the past, said Fogg, adding that the software can not only pinpoint what what wrong, when, and where, but it can alert supervisors to potential problems before they happen and keep shop owners from having to make phone calls like the one mentioned above.

“There are thousands of pieces of data that can be pulled from any discrete machine tool every minute, and all that data has value,” Fogg explained. “That data can tell you about loads on tools or about problems with any part of the manufacturing process.”

Effective retrieval and analysis of that data has enabled VSS to improve what’s known as OEE (overall equipment effectiveness) from around 70% to roughly 90%.

While visiting the war room at VSS, Bither explained just how the software works.

“Each ring represents a shift,” he explained while motioning toward the dashboard. “As the ring fills in, that’s indicative of how many parts are created; when the ring is completely closed, the goal is met for the shift. There’s a white dot that moves around the ring, and it’s essentially a rabbit that you’re chasing. If you’re ahead of the white dot or on it, it’s green; if you’re behind, then it’s orange or red.”

The system tracks performance in real time, said Traversa, adding that this represents a vast improvement over the conditions that existed before the software was installed.

The MachineMetrics system has made the phrase ‘being in the green’ — as most all of the machines at the company are at this moment in time — part of the lexicon at VSS.

Making Progress

Capshaw, who spoke with BusinessWest by phone while vacationing on the Cape, said the system allows him to see what’s happening at the shop on a host of devices. He noted that productivity at VSS has increased 10% not from really doing anything with the data specifically, but simply from having it and making sure employees know they have it.

Employees simply have to look up at the dashboards on the shop floor to track how the machines they’re assigned to are performing, he went on, adding that no one wants to see the color red appear, and everyone wants to stay firmly in the green.

Roughly another 10% improvement has come from going back over data, identifying issues, streamlining production, and improving maintenance, he went on.

“We look at how efficient we are shift by shift and product by product, and see where we need to improve,” he explained. “The result is that we can more finely tune our training programs for employees, which is typically the reason for downtime, or improve our maintenance system so we have more uptime on our machines.”

Thus, benefits come in a number of forms, he said, listing everything from enhanced productivity to improved morale, especially among third-shifters, who seemingly toiled in anonymity.

“We had employees come up to us after we put up the boards,” said Capshaw. “They worked third shift, and they said to us that, if they did a great job, they never got a pat on the back. But they said having this is like getting a pat on the back — they work to get back in the green, and we see that, and we e-mail them and congratulate them.”

Perhaps the biggest benefit, though, is some reduction in stress when it comes to the nagging issue of finding enough talent as a result of that improved efficiency.

“Instead of having to recruit and hire 40 employees, we’ll have to hire 30,” he said. “We’ll still have to hire a lot of people, but it will relieve that bottleneck, which allows us to expand quicker.”

Moving forward, the obvious goal for the principals at MachineMetrics is to scale up their venture, and the recent infusion of capital will be used for the many aspects of that assignment.

Fogg said one of the company’s major challenges, not unlike the one confronting its customers, is finding talent.

“We have a lot of customers who are interested in this product, but one of the difficulties is integrating it into the machines,” he explained. “That’s something I know how to do, but it’s very difficult to find people who know machine integration; we’re actively trying to hire people like that, but we can’t even find them, let alone give them offers for jobs.”

Overall, the potential for growth is immense, said Bither, adding that the market for performance-monitoring software in the precision-manufacturing sector will reach into the billions of dollars.

Just how big that number will get, he doesn’t know, but he does know Machine Metrics should be well-positioned to seize considerable market share.

“There are a few competitors, but this is fairly new technology, so there isn’t one company that’s out there dominating,” he explained, adding that a company in Germany and another based in Silicon Valley are gaining some traction in the industry, while others are struggling in their attempts to do so.

“Production-monitoring technology is still in its early stage,” he went on. “But there is a lot of opportunity, because these companies are recognizing that measuring data is critical to staying competitive; they have to be efficient to win these deals.”

It’s Not Easy Being Green

Throughout business history, company owners have made it their mission to both keep out of the red and be in the black. For precision manufacturers, there is now a third mantra — ‘being in the green.’

As mentioned earlier, this is now an informal mission statement and both a spoken and unspoken rallying cry at Valley Steel Stamp.

Just how prevalent that phraseology becomes in this industry remains to be seen, but from all accounts, MachineMetrics seems poised to turn out some solid growth patterns of its own.

And it also appears destined to be part of the wave of entrepreneurial energy sweeping over the region.

George O’Brien can be reached at [email protected]