Filling the Gap

New Programs Prepare People for Careers in Manufacturing

Several weeks ago, Bob LePage met with a fourth-generation manufacturer who is having problems finding new employees with the right skills to fuel his company’s growth.

“He told me his competitors were also having a difficult time and he gained new customers when another fourth-generation manufacturing company went out of business because they could not find enough talent,” said Springfield Technical Community College’s vice president of Foundation & Workforce Training.

In response to the growing need for skilled workers in the manufacturing sector, STCC launched several new programs this summer and expanded existing programs that provide training and retraining for careers in the field.

Specifically, STCC’s associate-degree program in precision machining doubled in size last September from 40 to 80 students, thanks to a $2 million upgrade of the school’s Smith & Wesson Technology Applications Center. “We have all new CNC machines, computers, high-end computer workstations, and software. We also hired two new faculty members as well as technicians,” said STCC President Ira Rubenzahl, adding that there will be a total of about 250 students in non-credit and for-credit manufacturing-related programs this fall.

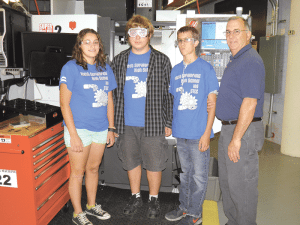

From left, West Springfield High School students Lexi Pastore, Jared Schelb, and Chris Brown prepare to make key fobs under the direction of STCC Professor John LaFrancis.

The accelerated program includes a combination of classroom and hands-on training in machining, and will continue this fall, with a class at STCC’s Smith & Wesson Center and another sponsored by HCC. The latter will consist of evening sessions held at Dean Vocational Technical High School, with hands-on training there and in the Smith & Wesson Center.

“The program provides students with production, foundational machining, and fabrication skills,” said LePage. It includes classes on machinery, instrumentation, LEAN production, blueprint reading, teamwork, and manufacturing math. Students are also given exposure to the industry via speakers and field trips.

When the first class graduates later this month, members will receive certificates of completion, OSHA 10-hour cards, and mechanical-aptitude certificates. Companies have already interviewed them in anticipation of the upcoming commencement, and LePage said starting salaries should between average between $35,000 and $40,000.

The program was funded by the Massachusetts Competitive Partnership, MassMutual, Suffolk Construction, and Smith & Wesson.

LePage said the college has weekly meetings with administrators at Smith & Wesson, who invested more than $200,000 in the center five years ago and continue to support it.

“Our plan is to expand the program; we want to offer it at UMass Amherst and in two other communities in addition to Holyoke,” he explained. “We need to grow capacity so we can meet the volume needs for the region.”

Other measures to fill the gap include an increase in the number of training sessions for employees of manufacturing companies, accomplished through a partnership with the Regional Employment Board of Hampden County (REB). It allows individuals and small groups working in the field to update their skills at the Smith & Wesson Center. Larger manufacturers with six or more employees have the option of sending them to the center or having instructors from the college conduct on-site trainings in their locations.

Credit and certificate programs are also part of the mix, and STCC offers a CNC certificate in design, a CAD-CAM certificate, and an associate’s degree in mechanical engineering technology. Classes are held four nights a week to meet the needs of people already employed who want to step up their careers, as well as those in traditional degree programs.

Early Exposure

STCC and its partners are also looking to the future, and this summer, the REB paid for a group of 10 students from West Springfield High School to attend a new, two-week summer session called “Pathways to Prosperity” at the Smith & Wesson Center.

The teens, who will be entering their sophomore year this fall, were selected by the school and were among a group of 60 students who toured the center in the spring. “The program gave us the opportunity to expose students from a non-vocational high school to manufacturing,” said John LaFrancis, professor of Mechanical Engineering.

The students learned how to design parts using computer software programs, then took the design for a small bottle-style container with four sides to a rapid prototyping machine.

LaFrancis said they worked as a group to decide what to emblazon on two sides of the container, and chose their high-school Terrier logo for one side and put their names and/or a quotation on the other.

“This was an additive process which required them to add material to manufacture their bottles,” said LaFrancis. “Each student got to keep their container, and they will make good holders for pens and pencils.”

The students also chose a design for a brass key fob, and emblazoned ‘STCC’ on one side and their name or something else on the flip side. “The key fob was a subtractive process in which they removed material to reveal their individual designs,” LaFrancis explained. “The program has been a real success, and we would like to hold it again. But we want to expand it to two campuses so we can expose more students to manufacturing.”

STCC and its partners are doing all they can to meet that goal and interest young people in manufacturing. “The program was part of a strategy to build awareness about career opportunities,” LePage said.

Rubenzahl added that exposure to opportunities in manufacturing should start in middle school. “Students can have careers as engineers, run CNC machines, do design work, programming, quality control, or go into sales and marketing,” he noted. “Manufacturing is a hot field for employment in the Pioneer Valley, and, given the economy, it’s important for people to understand this and take advantage of it, because if there are not enough new employees, companies won’t survive.”

One reason for the shortage of skilled workers is the number of Baby Boomers who are retiring. “We believe the region will need 300 to 400 workers in the next few years,” said LePage. “One company that recently partnered with us told me they expect to lose two-thirds of their staff to retirement.”

The need has echoed throughout the Valley, and the new programs have been created through proactive collaborations with the REB, Holyoke Community College, and high schools with vocational technical programs, as well as information elicited from local manufacturers.

“We’ve been working to improve our ability to educate students for the manufacturing sector for 10 years, and people are wowed by what we are doing,” said Rubenzahl. “Manufacturing is the most important sector for revitalization in the Pioneer Valley; the area was a center for manufacturing during the 19th century, and there are many legacy companies, new companies, and a lot of skill in terms of business acumen to build on. An expansion of manufacturing will be the basis for building a robust economy here. Plus, these jobs pay well, and the college wants to provide the education students need to get good-paying positions.”

He added that STCC’s partnerships with manufacturers are growing in number, which heightens the school’s ability to link graduates to jobs while raising awareness about career opportunities through tours and informational sessions.

Solid Foundation

LePage said many people are unaware of the number of small manufacturers in the region who provide specialized products for the medical, auto, and aerospace industries. Pay for entry-level positions averages from $12 to $17 an hour; people with a one-year certificate earn between $40,000 and $50,000, and those with an associate degree gross about $50,000, or $70,000 with overtime.

Bob LePage, left, and John LaFrancis show off one of the new machines in the Smith & Wesson Technology Application Center at STCC.

Although STCC and HCC have created new programs, Rubenzahl said economic-development agencies and department heads need to place more emphasis on manufacturing. “I believe they need to make it an important priority because there is a huge potential future in terms of jobs and industry growth if we can all get on the same page,” he told BusinessWest.

He cited, as one example, the $1.5 billion appropriated by the Legislature to replace rail cars on the Mass. Bay Transit Authority Orange and Red lines, since it has been mandated that they must be manufactured in the state.

“We would like Western Mass. to become so prominent in the manufacturing sector that it would be the logical and most cost-effective place to do this work,” LePage said. “But we need to raise our game to be able to attract that type of business.”

This requires an educated workforce, especially since the manufacturing sector is very dynamic and large capital investments are required for companies to be successful. “We can’t compete with Mexico and India in terms of labor, but we can compete by making high-end devices, which are some of the key products which companies in this region specialize in,” Rubenzahl said, adding that he spoke to a manufacturer who showed him a $1 million machine and said he would be happy to pay someone $50,000 to $60,000 a year to run it.

“Companies have made huge investments in order to be successful, but they need highly educated people,” he went on. “And there are a lot of small, local companies here doing tremendously sophisticated work.”

Future Outlook

LePage argues that long-term planning has been critical in developing the new programs. “No one institution can solve the problem — it takes a collaborative regional approach,” he said. “But we plan to continue to add new components to our program at STCC meet the region’s needs.”

Gary Masciadrelli, chair of the Mechanical Engineering Technology Department, agreed.

“STCC is fully supportive of supplying the manufacturing industry with current and future workers today, evidenced by our programs in the high schools and for adult learners,” he said. “We look forward to continuing them in the future to meet demand.”