Community Spotlight

Jacob Robinson took the helm at the Amherst Area Chamber of Commerce earlier this month.

After relocating to Belchertown a few years ago, Jacob Robinson found himself a frequent visitor to nearby Amherst and admits to falling in love with its downtown — as many do.

He confided to BusinessWest that, on more than one occasion, while walking along South Pleasant Street and passing the building that houses the town’s chamber of commerce, business improvement district, and visitors’ center, he thought to himself, “how cool would it be to work in a place like that?”

And now … he gets to answer that question.

Indeed, late last month, Robinson was named executive director of the Amherst Area Chamber of Commerce, and he took the helm on April 1.

“No joke,” he said in reference to his start date, adding that what he likes about the job, and what prompted him to seek it, besides its mailing address, is that it involves high levels of collaboration and the fostering of partnerships, which he believes are personal and professional strengths gained from more than 15 years of work with various nonprofits, most recently the West Roxbury Main Streets program, which he served as director.

“There’s a special energy to this town,” he said when asked what attracted him to the position. “And I wanted to be part of it.”

Robinson’s arrival is one of the many converging storylines in this community, known for its liberal leanings; college-town character; rich mix of museums, restaurants, and other tourism and hospitality businesses; its reputation as a great community to retire to; and a bustling, ever-changing downtown.

“There’s a special energy to this town.”

Others include a nearly $50 million expansion and renovation of the Jones Library; a $2 million renovation of the North Common adjacent to Town Hall; new businesses, such as the Aster & Pine Market, a specialty store, which cut the ceremonial ribbon on April 20; and a number of ongoing residential and mixed-use projects that will address a perpetual need for more housing while also, in many cases, bringing more vibrancy to the downtown.

These include several being developed by the Roberts Group, including a much-anticipated re-imagining of the property (just a few doors down from the chamber) known as the Hastings Building, because it was home to the legandary office-supply store for more than a century, and new construction on adjacent property.

An architect’s rendering of the planned mixed-use development at the Hastings Building and adjoining property on South Pleasant Street.

Barry Roberts, president of the Roberts Group, said plans call for six units of market-rate housing on the upper floors of the Hastings Building and the Amherst College bookstore on the ground floor, with work on the latter already underway, with the goal of that facility being open for commencement. The adjacent 55 South Pleasant St. will be torn down, as well as property that served as cold storage for Hastings, with a five-story property to be built on that site that will feature 16 units of market-rate housing.

Meanwhile, another, much larger project is being planned for the former Rafters sports bar property at the corner of University Drive and Amity Street, most recently home to Pleasantrees, a cannabis dispensary that closed after operating for only a year. The site will be transformed into 85 units of housing in two five-story buildings, as well as retail and office space (more on this later).

There are also some ongoing stories, such as the Drake, the live-event space that brings hundreds of people to the downtown for shows each week; White Lion Brewing Co., located in the same building as the Drake, which is still acclimating to doing business in Amherst six months after opening (more on that later as well); and the largest of these ongoing stories — continued recovery from the pandemic, which devasted a business community that is largely dependent on the students, faculty, staff, alumni, and parents from the surrounding colleges.

For this latest installment of its Community Spotlight series, BusinessWest turns its lens on Amherst, a community that is in a seemingly constant state of motion — and change.

What’s on Tap?

Ray Berry has been in business with White Lion, launched in Springfield, for several years now, but he told BusinessWest that his location in Amherst amounts to a learning experience on several levels, with new lessons every day.

Indeed, he said the intriguing nature of this community — it’s not just a college town, but a three-college town with two more just a few miles away — presents challenges and opportunities that are unique and require some … well, getting used to.

“As a business, we continue to learn from the ebb and flow of the Greater Amherst community; every day is a learning process.”

“As a business, we continue to learn from the ebb and flow of the Greater Amherst community; every day is a learning process,” he said. “Whether it’s the population coming and going or special events in the town, we continue to learn and appreciate; it’s all new to us.

“In Springfield, we have pretty much 24/7, 365-days-a-year activity — there’s plenty of activity, and we don’t have to incorporate the university population that’s close by,” he went on. “But in Amherst, we have to be very mindful of how the university and private-college student activity, and faculty activity, impact the day-to-day business community.”

Elaborating, he said White Lion, now proudly serving Marcus Camby New England IPA, which is especially popular in Amherst, has operated through winter break, spring break, St. Patrick’s Day, March Madness, and other annual happenings, but the learning process will continue when the colleges shut down, or mostly shut down, for the summer and then reopen in September.

Learning these ebbs and flows is part and parcel to doing business in Amherst, noted Robinson, who is on a learning curve himself. Indeed, while already quite familiar with the town, he will now take his knowledge to a much deeper dive, while also getting further acquainted with the other six towns represented by this chamber, all with their own distinct personalities: Belchertown, Hadley, Leverett, Pelham, Shutesbury, and Sunderland.

Since arriving, Robinson has been busy with everything from staging one of the chamber’s signature networking and fundraising events, Margarita Madness, to planning the next events, including After-5s, workshops, and a new-member reception coming up in May, as well as early-stage work to hire a new marketing and events coordinator for the chamber.

“I’ve had to hit the ground running,” he said, adding that the chamber position presented a unique opportunity for him to continue what he calls “community work,” as both a volunteer and a nonprofit leader, most recently with Main Streets program in West Roxbury.

Amherst at a glance

Year Incorporated: 1759

Population: 39,263

Area: 27.7 square miles

County: Hampshire

Residential Tax Rate: $18.51

Commercial Tax Rate: $18.51

Median Household Income: $48,059

Median Family Income: $96,005

Type of Government: Select Board, Town Meeting

Largest Employers: UMass Amherst; Amherst College; Hampshire College

* Latest information available

He was commuting to that job from Belchertown — though also working remotely, to a large degree — when his brother-in-law brought the posting for the executive-director position at the Amherst Area Chamber to his attention. He applied with the intention of enthusiastically taking part in building on what he saw, heard, and experienced during all those visits to downtown Amherst — its restaurants, coffee shops, and theater.

“There is so much charm here; there’s the connection to the universities, the energy that comes from all those students, and the vibrancy of a town that’s connected to the college communities,” he said. “There’s a healthy mix of businesses and services, and that’s very telling of a dynamic and strong community here in downtown Amherst.”

Building Momentum

Long-term, the obvious goals are to continue building partnerships and creating collaborative efforts to promote the community, attract new businesses, and continue the ongoing recovery from the pandemic, which, as noted, hit this community perhaps harder than any other in the region because it shut down the Five Colleges and removed from the business equation tens of thousands of people and countless gatherings, from sporting events to commencements.

“It was very tough on everyone — it was shocking. Who would ever have imagined that the universities and the colleges would be closed for that length of time?” recalled Lisa Johnson, president of Encharter Insurance, the latest name on an Amherst institution that has been around since the late 1800s. “It was shocking to be on the streets and have them be so quiet.

“But the bounceback has been strong even though it took a while before people started coming out again, even the students,” she went on, adding that, perhaps because of the hard lessons learned during the pandemic and its aftermath, she believes the town and its business community are devoting more time and energy to attracting visitors while being slighly less dependent on the colleges.

Which is why she is encouraged by projects like the ones planned for Amity Street and the Hastings Building, initiatives that will bring more residents, but also opportunities for new businesses to settle in the community.

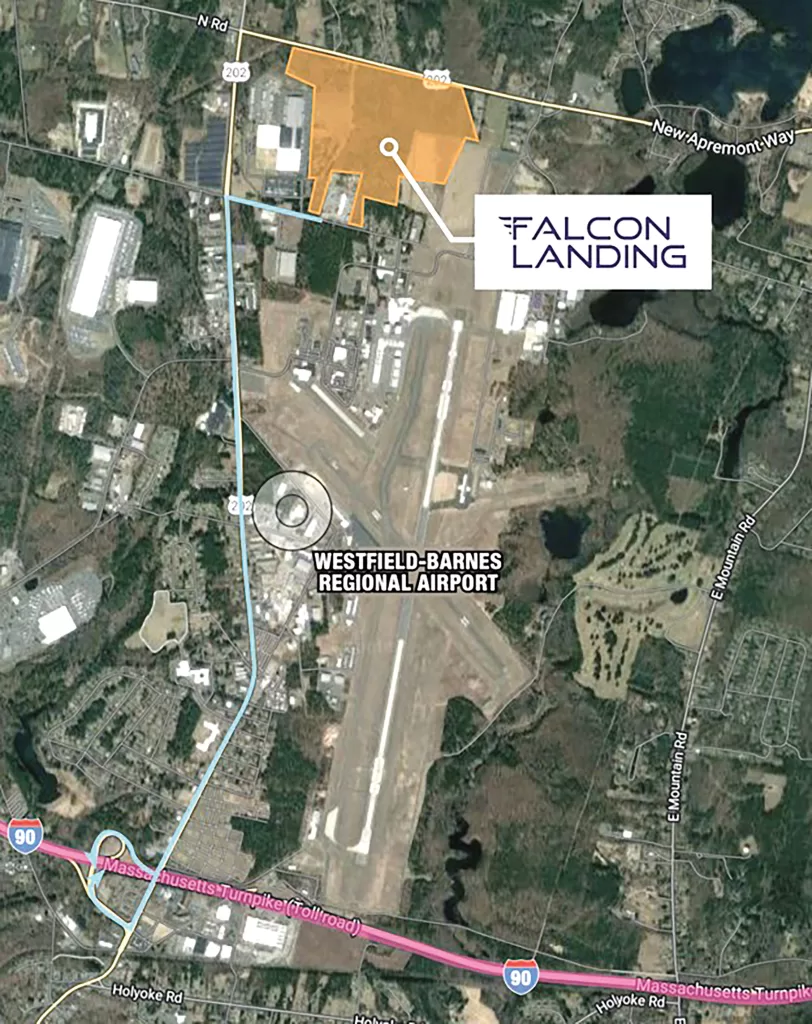

Roberts agreed, telling BusinessWest that, by and large, his ongoing projects are simply taking the names of their street addresses. Like ‘422 Amity.’

This is the the mixed-used project at the old Rafters property, and one that has the potential to change the landscape, in all kinds of ways.

The 85 units of housing will help meet an enormous need in that realm, he said, adding that the complex will bring new retail and new office tenants — and, therefore, more vibrancy — to that area just a few hundred yards from the UMass campus and a few blocks from downtown.

“It will even provide the town with the opportunity to apply for a Community Development Block Grant to put a roundabout at that crazy intersection there,” said Roberts, whose company has been, in a word, busy over the past few years.

Indeed, it has been involved in a number of initiatives, from the Drake project to bringing new tenants to several properties downtown, to another ambitious housing project, this one called 180 Fearing St., or simply One Eighty, which is in its final stages of construction and is fully rented through 2026.

The complex of duplexes features 22 versatile units ranging from studios to four bedrooms, said Roberts, adding that it has succeeded in attracting a wide range of tenants, from students and young families to professionals to retirees, which was the goal when it was put on the drawing board several years ago.

“This is an exciting project, and it has attracted an intriguing mix of tenants that really reflects the Amherst community — students, professionals, and retirees alike,” he said, adding that the same is expected from the project on the Hastings site, as well as another initiative in its early stages: the razing of a building across South Pleasant Street from the Drake — home to the former McMurphy’s bar and the Knights of Columbus — and construction of high-end condos (with accompanying parking) and commercial businesses on the street level.

“We’re still working on getting the permitting,” said Roberts, adding that this hurdle should soon be cleared, and another endeavor to bring more people, and vibrancy, to the downtown will be underway.

“As planners, these changes often prompt investigating alternative ways to pass on wealth earlier to heirs, including layering in additional diversification with investments spread between retirement accounts, Roth IRA/401(k) plans, and non-retirement assets.”

“As planners, these changes often prompt investigating alternative ways to pass on wealth earlier to heirs, including layering in additional diversification with investments spread between retirement accounts, Roth IRA/401(k) plans, and non-retirement assets.”

“Many people today do not have access to pensions like the generation before us. So that means investing early and wisely is paramount to building the wealth needed to achieve your retirement dreams.”

“Many people today do not have access to pensions like the generation before us. So that means investing early and wisely is paramount to building the wealth needed to achieve your retirement dreams.”

“None of us want to feel like we’re toiling away alone. We want to feel like we’re part of a larger ecosystem.”

“None of us want to feel like we’re toiling away alone. We want to feel like we’re part of a larger ecosystem.”