Exciting STUFF

John Cook, president of Springfield Technical Community College, proudly displays the cribbage board given to him by students at Pathfinder Regional Technical High School in Palmer

John Cook, president of Springfield Technical Community College, says he doesn’t play the card game cribbage.

But that doesn’t mean the cribbage board given to him recently gathers dust sitting in a drawer or closet unused. In fact, it now occupies a prominent place on a desk already crowded with items that speak to his personal life and career in higher education.

That’s because the elaborate board was crafted by students at Pathfinder Regional Vocational Technical High School in Palmer. It’s fashioned from metal — Cook isn’t sure exactly what the material is, although he suspects it’s aluminum — and it’s truly a one-off, complete with his name and title printed on it.

That’s because the elaborate board was crafted by students at Pathfinder Regional Vocational Technical High School in Palmer. It’s fashioned from metal — Cook isn’t sure exactly what the material is, although he suspects it’s aluminum — and it’s truly a one-off, complete with his name and title printed on it.

As noted, Cook’s never used the gift for its intended purpose, but he’s found an even higher calling for it.

“I take this around, and I tell people that, if they can create one of these at one of those labs like the one at Pathfinder, there’s a $50,000-a-year job waiting for you,” he said as he started to explain, making it clear that his cribbage board has become yet another strategic initiative in a multi-faceted effort to educate people about careers in manufacturing and inspire them to get on the path needed to acquire one.

Other steps include everything from taking young people on tours of area plants — and their parking lots (more on that later) — to working with the parents of those people to convince them that today’s manufacturing jobs are certainly not like those of a generation, or two, or three, ago.

“I take this around, and I tell people that, if they can create one of these at one of those labs like the one at Pathfinder, there’s a $50,000-a-year job waiting for you.”

And there’s good reason for all the time and hard work put toward this cause. It’s all spelled out in the latest Workforce Development and Technology Report prepared as part of the Precision Manufacturing Regional Alliance Project, or PMRAP for short.

Indeed, the numbers on pages 7 and 8 practically jump off the page. The chart titled ‘Workforce Indicators’ reveals that the 41 companies surveyed for this report project that, between new production hires and replacement of retiring employees, they’ll need 512 new workers this year. Extrapolate those figures out over the entire precision-manufacturing sector, and the need is 1,400 to 1,500, said Dave Cruise, president and CEO of the MassHire Hampden County Workforce Board, formerly the Regional Employment Board of Hampden County. Meanwhile, the number of people graduating annually from programs at the region’s vocational high schools and STCC is closer to 300, he said, noting quickly, and with great emphasis, that not all of those graduates, especially at the high-school level, will go right into the workforce.

Those numbers translate into a huge gap and a formidable challenge for this region and its precision-manufacturing industry, said Cruise, Cook, and others we spoke with, adding that additional capacity, and a lot of it, in the form of trained machinists, must somehow be created to keep these plants humming. But before finding the capacity (the expensive manufacturing programs) required to train would-be machinists, the region must create demand for those programs. Right now, there certainly isn’t enough, hence strategic initiatives involving everything from plant tours to Cook’s traveling cribbage board.

BusinessWest has now become an active player in this initiative with an aptly named special publication called Cool STUFF Made in Western Mass. It’s called that to not only confirm that there are a lot of intriguing products made in this region — from parts for the latest fighter jets to industry-leading hand dryers to specialty papers — but to grab the attention of area young people; Cool STUFF will be distributed at middle schools and high schools with tech programs, regional workforce development offices, state college career counseling offices, non-manufacturing employers, top manufacturing firms, BusinessWest subscribers, guidance counselors, community colleges, and employment offices.

Sponsored by the Massachusetts Technology Collaborative, the Massachusetts Manufacturing Extension Partnership, Associated Industries of Massachusetts, and MassDevelopment, Cool STUFF will include a number of profiles of area companies. These profiles will list the products made, the customers served, and the markets these companies supply. But the most important details are the job opportunities, the benefits paid, and the thoughts of those working for these companies.

As BusinessWest continues work on Cool STUFF, to be distributed later this fall (companies interested in purchasing profiles can still do so), it will use this edition of the magazine to set the table, if you will, by detailing the size and scope of the challenge facing this region when it comes to its manufacturing sector, and also highlighting many of the initiatives to address it.

Making Some Progress

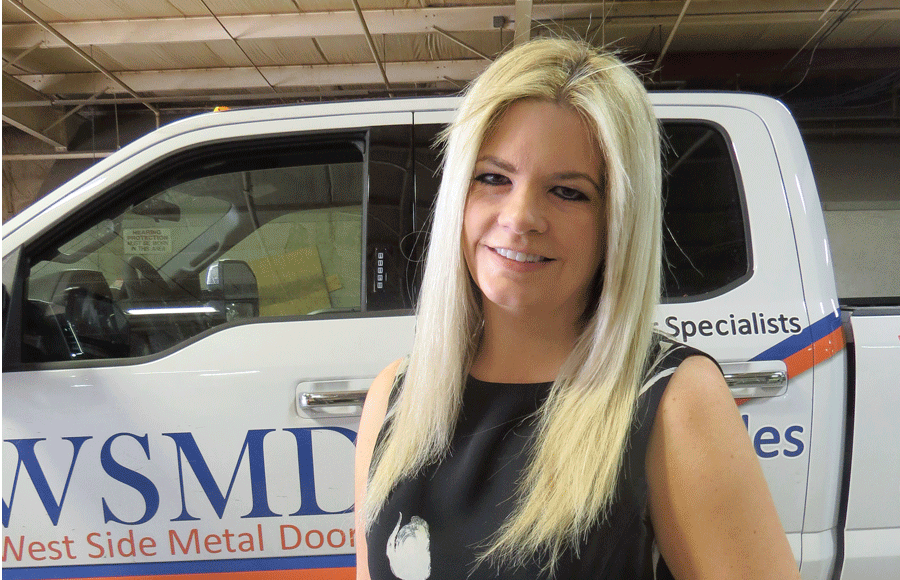

Kristen Carlson is working on the front lines of the manufacturing sector’s workforce challenge — in a number of capacities, first as president of the local NTMA chapter, which has about 60 members, but also as owner and president of Peerless Precision in Westfield, a maker of parts for the aerospace and defense industries.

Kristin Carlson, owner of president of Peerless Precision, says area precision shops are very busy; the only thing holding them back is finding enough good help.

She told BusinessWest that business is booming for Peerless and most other precision manufacturers in this region, and it’s likely to stay that way for the foreseeable future — a fact lost on many not familiar with the high quality of work carried out at area shops and this region’s reputation across the country and around the world as a precision hub.

“In the precision-machining side of the manufacturing sector, companies are not leaving this area,” she explained while debunking one myth about this industry. “There is a skilled workforce here that other states simply cannot compete with. So while it might cost a company less to do business in Tennessee or South Carolina, for example, they’re not going to see the same skill that we need in order to produce the parts our customers need.

“Right now, every industry is booming — aerospace, defense, oil and gas, even the commercial sectors,” she went on. “A lot of us are seeing really large growth percentages over the past 12 months; the only thing that’s holding us back is having the workforce to fill the jobs that we have.”

Peerless has seen 30% growth over the past year, and added six new people over the first six months, she continued, adding that, several years ago, the pace would have been closer to one new person a year.

“I could double in size if I had the workers,” she told BusinessWest, adding that there are many in this sector who could likely say the same thing.

The challenge of inspiring more individuals to become interested in manufacturing is not exactly a recent phenomenon in this region; it’s been ongoing for some time. However, the problem has become more acute as shops continue to add work and also as the Baby Boom generation moves into retirement.

The problem becomes one of supply and demand. There is considerable demand, but simply not enough supply. In most matters involving this equation, supply usually catches up with demand, but this situation is different in many respects.

Indeed, there are many impediments to creating supply, starting with perceptions (or misperceptions, as the case may be) about this sector and lingering fears that jobs that might be there today won’t be there tomorrow. These sentiments are fueled by memories of those with the Boomer generation, who saw large employers such as the Springfield Armory, American Bosch, Uniroyal, Diamond Match, Digital Equipment Corp., Westinghouse, and others disappear from the landscape.

Dave Cruise says surveys of area precision manufacturers reveal a huge gap between expected need for workers and the region’s ability to supply them.

Meanwhile, another challenge is creating capacity. Manufacturing programs are expensive, said Rick Sullivan, president and CEO of the Economic Development Council (EDC) of Western Mass., adding that it’s also difficult to find faculty for such facilities because potential educators can make more money working in the field than they can in the classroom.

Regarding those perceptions, the obvious goal is to change the discussion, or the narrative, surrounding manufacturing, said Sullivan, by driving home the relative security of most jobs today and the fact that “these are not your grandfather’s manufacturing jobs.”

“Manufacturing today … is not, for the most part, standing at a machine doing some kind of manual labor,” he told BusinessWest. “The high-end precision manufacturers today are very technology-driven; there’s lot of computer science, lots of IT. It’s a clean environment, and the jobs in manufacturing, especially precision manufacturing, are very-good-paying jobs, and you can have a very good middle or upper-middle lifestyle, particularly in Western Massachusetts.”

Cook, whose school has several manufacturing programs and is the region’s clear leader in supplying workers for the industry, said that, despite the costs and challenges, additional capacity can and will be created — if (and this is a big if) demand for such programs grows and becomes steady.

That’s why Carlson and others say that manufacturers must sell this sector and its employment opportunities to not only the region’s young people, but also their parents.

“And their parents are often the harder sell,” said Carlson. “If I have a class of 20 kids come in and three or four or five of them show a real interest in manufacturing, I consider that a good day. But then, those kids go home, and selling it to their parents is the difficult part, because many of them still believe this is your grandfather’s machine shop — it’s a dark, dingy place, and only people who can’t go to college do that work, which is not the case.”

Meanwhile, young people are not the only targets. Indeed, other constituencies include those who are unemployed and underemployed, those looking for new careers, and the region’s large and still-growing African-American and Latino populations.

Across all those subgroups, women have become a focal point, in part because they — and, again, their parents — have not looked upon manufacturing as a viable career option when, in fact, it is just that.

“We know there are really well-paying jobs out there, but there’s a lot of work to be done to invite new individuals into this career path,” said Cook. “And I talk about two groups in particular — women and students of color — and there’s work to be done there. We have to engage families, and at much younger ages.”

Still Some Work to Do

It’s called the Twisters Café.

That’s the name given to a ’50s-style diner at Sanderson MacLeod in Palmer, a maker of twisted wire brushes for the cosmetic, healthcare, handgun, and other markets.

It was created a year or so ago, not long after the company also added an appropriately named ‘appreciation garden,’ an outdoor break area complete with picnic tables, chairs, umbrellas, and more.

The additions are part of ongoing efforts to make the workplace more, well, livable and attractive to employees and potential employees.

“They’re little things, but they make this a better environment,” said Mark Borsari, the company’s president. “People are here more than they’re at home, and we hope these steps make this a more enjoyable place to be.”

Those sentiments are yet another indication of how manufacturing has changed in recent years. And making people aware of not just perks like the Twisters Café, but also, and more importantly, the jobs and careers available in manufacturing today, is the broad, multi-faceted mission of a growing group of individuals, agencies, and companies.

This constituency includes the EDC, the various MassHire agencies, the vocational high schools and STCC, the NTMA, and individual manufacturers.

Shop owners will go into the schools themselves to talk about what they do and how, said Sullivan, and the shops will host tours of students, taking them onto the floor, and later into the parking lot.

“That’s a big part of these tours,” he said. “They show the students what they can do, what they can have, with the money they can earn from one of these jobs.”

And such initiatives are starting to generate results on some levels, said Sullivan, noting that many of the vocational schools now have waiting lists, especially for their manufacturing programs — something that didn’t exist a decade ago or even five years ago, when such schools were largely viewed as the best option for students not suited for a typical college-bound curriculum.

But those numbers on pages 7 and 8 of the PMRAP report show there is still a huge gap between demand and the current supply, and therefore there is still considerable work to be done, said Cruise, noting that the goal moving forward is to reach more people overall, more young people, and young people at an earlier age.

Cook agreed, and to get his point across, he brought out another item he’s collected — a fidget spinner made by a young student during a summer STEM program staged at the STCC campus.

“We have to do more of that,” he explained. “We have to do more work with younger students; we have to engage their families over the summer, and we have to let the young people get their hands on the equipment and build things like this. And we have to do things like this at scale — we have to start inviting far larger groups of students to our campus to see these programs.”

Cook does a lot of promotional work for the manufacturing sector — and STCC’s programs — himself, and his cribbage board is very often part of the presentation.

“I bring it to meetings every once in a while,” he explained. “It’s that teacher in me that still likes to use something physical for people to see, to touch, and to hold. They can realize that there’s still a very important place for this in our economy, and there’s nothing better than to put this into people’s hands and make them realize that that’s something significant about the ability to generate something like this.”

Cool STUFF will hopefully act like that cribbage board in that young people can see the products many area companies are making, and, in the snapshot profiles of these company’s employees, they can maybe see themselves in a few years.

“Manufacturing has a rich history in this region, but too many people think ‘history’ means ‘in the past,’” said BusinessWest Associate Publisher Kate Campiti. “There’s still history being written in this sector, and the future looks exceedingly bright. Cool STUFF will hopefully drive this point home and encourage young people to include manufacturing in their list of career options.”

Parts of the Whole

Carlson was talking about the salaries and benefits offered by her company — most workers are paid $1,000 a week or more — when she paused for a moment.

“When you add up wages, overtime, and everything else, there are a few guys here making more money than I do,” she said, adding that this is not an exaggeration, but it is a fact lost on many young people, their parents, and other constituencies.

Bringing such facts, and numbers, to life is an ongoing priority for the region, and Cool STUFF will become part of the answer moving forward, as will John Cook’s cribbage board, plant parking-lot tours, and much more.

The stakes are high, but so is the number of opportunities — for potential job holders, the companies that will employ them, and the region as a whole.

People need to be made aware of these opportunities, said all those we spoke with, and, more importantly, inspired to reach for them.

(For more information on Cool STUFF Made in Western Mass., on how to have your company profiled, for advertising opportunities, and to receive copies, call (413) 781-8600.)

George O’Brien can be reached at [email protected]

That’s because the elaborate board was crafted by students at

That’s because the elaborate board was crafted by students at