Manufacturing Field Is Turning More Heads

Making Some Progress

Elizabeth Ryan, working her way toward a bachelor’s degree in advanced technology systems, wants to move on to a leadership position in the manufacturing field.

While the region’s manufacturers continue to struggle to find qualified help and fill the enormous voids being left by retiring Baby Boomers, it appears that some progress is being made in efforts to inspire young people to consider the field and start down a path toward a career within it. Conversations with students at Springfield Technical Community College reveal that, while considerable work remains to be done to meet the workforce needs of this sector, some perceptions about it are changing.

Gary Masciadrelli said the letters keep coming.

And to back up those words, he started shuffling papers on his desk to find some. He didn’t have to look far or work hard.

“Here’s one — a local company looking for an intern,” said Masciadrelli, professor and chair of the Mechanical Engineering Technology Department at Springfield Technical Community College, as he held it aloft. “Here’s another one … someone looking for a manufacturing engineer. We get a letter almost every day or every other day. We’re constantly getting these demands for people to fill jobs; we could definitely use more students.”

Indeed, a number of area manufacturers are turning to STCC and Masciadrelli for some kind of help with a large and ongoing problem — finding enough talented help to help the steady steam of orders these companies are getting, especially as members of the Baby Boom generation reach retirement age.

“We have far more job opportunities than we have people to fill them,” said Masciadrelli as he talked with BusinessWest in his small office within STCC’s Smith & Wesson Technology Applications Center, equipped with state-of-the-art equipment on which students can train.

That ‘we’ he used referred to both the college — which has plenty of unused seats within both its associate-degree program and a new program launched in conjunction with Northeastern University whereby students may earn a bachelor’s degree on the STCC campus — and the manufacturing sector itself.

By some counts, there are hundreds of jobs, maybe more, within the region’s manufacturing sector that could be filled but have not been because there are simply not enough trained individuals. Changing this equation has become one of the top workforce-development priorities within the 413, which has a rich history in manufacturing and innovation dating back to the creation of the Springfield Armory (on what is now the STCC campus, ironically).

Masciadrelli told BusinessWest he’s doing what he can, but it remains a stern challenge to interest young people in this profession. Reasons vary, but at the top of the list are outdated perceptions about what the work is like; lingering doubts, fueled by talk about everything from robots to work going overseas, about the relative health of the sector moving forward; and strong memories among parents who saw stalwarts ranging from American Bosch to Moore Drop Forge to the Springfield Armory abruptly close their doors.

But some young people are managing to look beyond all that and see the vast potential that work in this sector holds. Many have role models, if you will — relatives or friends who stand as inspiring examples. And many are women, introduced to the field in high school and encouraged to continue down that path.

People like Lineisha Rosario, from Agawam, who started down the road to STCC and its mechanical engineering program (quite literally) while watching her father work on cars and becoming fascinated with how things worked.

“I was always with him and always willing to help, even though he didn’t let me because I was too little,” said Rosario, currently working for CNC Software Inc. in Tolland, Conn., which provides state-of-the-art software tools for CAD/CAM manufacturing markets, in the post-processing department.

She plans to continue working there after earning her associate’s degree in a few months, and encourages others to explore a field where they can stretch their imagination and expand their career horizon.

And also people like Elizabeth Ryan, who earned her associate’s degree at STCC and is now working toward her bachelor’s through the affiliation with Northeastern.

A graduate of Chicopee Comprehensive High School, she currently works as a mechanical engineer at Parts Tool & Die, an aerospace machine shop based in Agawam. She enjoys her current work handling programming, processing, and quoting, but has set her sights much higher.

“I want to move up the chain and see if I can get into a leadership position,” she explained. “I’m still fairly new to the industry since I’ve only been in it a year and half, but I have a lot of options now.”

Lineisha Rosario, currently working for CNC Software, says there are many career options for those looking to enter the broad field of manufacturing.

Indeed, she does, and this is the message that Masciadrelli and all those in the manufacturing sector want to get across loud and clear.

For this issue and its focus on workforce development, BusinessWest talked with Masciadrelli and several of the students enrolled in the programs at STCC. Their comments reveal that, while there’s still considerable work to do to close that gap noted earlier, this sector may be starting to turn some heads — as well as some cutting-edge parts for everything from the aerospace industry to the medical-device field.

Breaking the Mold

For many years now, area manufacturers, technical high schools, STCC, and workforce-development-related agencies such as the area regional employment boards have been working diligently to inspire young people — and their parents — to at least give manufacturing a hard look.

Programs have enjoyed varying degrees of success, but some progress has definitely been made when it comes to debunking myths and enlightening people about the opportunities to be found in this field.

For evidence of this, one needs to spend only a few minutes with Tim Vovk.

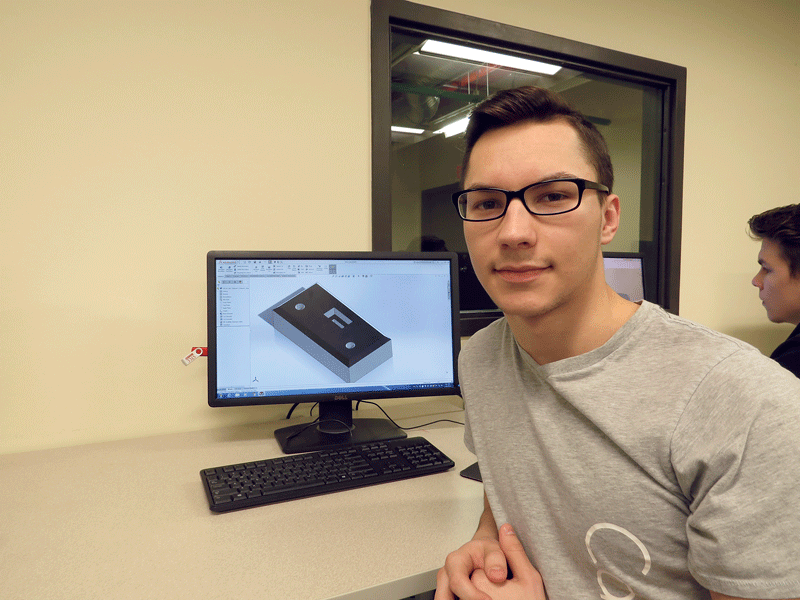

A graduate of West Springfield High School last May, he started work toward an associate’s degree at STCC last fall, more than four years after he signed up for something called the Pathways to Prosperity program, which introduces area young people to the manufacturing field while in high school.

“I thought to myself, ‘I might as well get to know the field; if I don’t like it, I can always leave it,’” he told BusinessWest. “I took the chance, and I grew to like it, especially the problem-solving aspect of it.”

Inspired by his cousin, a drafter at Pratt & Whitney, Vovk wants to follow a similar path because of the challenging and rewarding nature of design work.

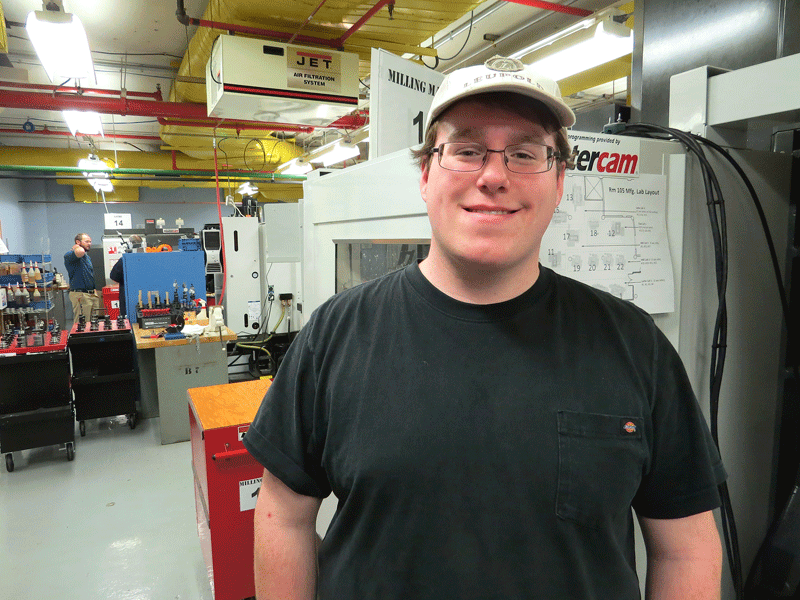

Tim Vovk says he was introduced to manufacturing while in high school, and he grew to like it, especially the problem-solving nature of the work.

“I’m enjoying it even more than I thought I would,” he said, referring specifically to solid modeling and blueprinting. “It’s fun to see a concept take shape.”

The region — and area manufacturers — could use at least a few hundred individuals more like Vovk, and they’re a long way from getting there. But his story, or individual components of it (that’s an industry phrase), are becoming more common thanks to ongoing efforts to promote the industry, create pathways to enter it and thrive within in it, and provide people with the skills that area manufacturers are desperate for.

And STCC is at the forefront of all that, with new facilities (the Smith & Wesson Center), new programs such as the affiliation with Northeastern, and solid relationships with a number of area manufacturers, said Masciadrelli as he talked with BusinessWest just prior to a class (called Solid Modeling for Mechanical Design I) involving freshmen enrolled in the associate-degree program in mechanical engineering technology.

These students, mostly younger individuals but some looking for a new career opportunity, spent the first semester on basic modeling and learning software. In this spring semester, they are learning what Masciadrelli called the “mechanics of design,” meaning proper drawing standards, geometric dimensioning and tolerancing, and understanding how to put all that on blueprints, and, in general, understanding the language of design.

By the time they earn their degree roughly 15 months later, and probably well before that, they could be owning jobs in several different realms, including design (CAD); manufacturing, such as using Mastercam programming; and the broad ‘quality’ realm.

While those at STCC are training students for the field, they’re also trying to sell young people and their parents on a profession. And in most respects, it remains a hard sell, said Masciadrelli.

“You have to get into the high schools and get to the guidance counselors and the parents as well,” he explained. “They need to be made aware that this field has changed and there are some great opportunities for good-paying jobs and careers.

“Technology has changed the field of engineering tremendously,” he went on. “Things that were done by hand … the computer has taken over everything. Look at CNC machining; people are no longer running a Bridgeport, turning cranks and feeling the work. The computer runs the CNC machine; with the technology involved, a lot more people can get involved in this work.”

And by all indications, there will be plenty of work in the years and decades to come, he continued.

Currently working at GKN Aerospace in Connecticut, Amanda Cyr is working toward her bachelor’s degree and, hopefully, a leadership position in manufacturing.

“The people at Pratt & Whitney are telling me they’re seeing no changes in he current demands for decades,” said Masciadrelli. “They never been so busy.”

He said the affiliation with Northeastern will help in this regard, because it will enable people to earn a four-year degree while they work (this is a night program) and in Springfield, as opposed to Boston or Amherst (UMass). And with that degree, new doors of opportunity can be opened.

“We want to show people what a great opportunity they have right here,”Masciadrelli explained. “You come here, spend two years, get a job — you’ll definitely be working when you graduate, and probably well before that — and while you’re working, you can complete your bachelor’s degree at night on this campus.”

There are actually two offerings through the affiliation with Northeastern — a degree in mechanical engineering technology (an offering that did not attract enough students to become reality this year), and another in advanced technology systems, which has attracted six students for this spring, including Ryan.

Where Dreams Take Shape

Perhaps the best selling tool the college has when it comes to its programs and the profession as a whole, Masciadrelli said, are individuals like its graduates and current students (most all of them already working in the field as well).

Through word-of-mouth referrals, they let others become aware of everything from the ample supplies of jobs available to the attractive salaries they offer. Through their stories, they effectively communicate that careers in this field are desirable and, contrary to popular opinion, not beyond their reach academically.

David Nawrocki, a graduate of Chicopee Comprehensive High School, tells a story heard often at STCC.

“Originally, I was going to do the engineering science transfer and transfer from here to UMass, but then I saw the course list, and I felt like a wanted to cry,” he explained. “I’m not really into Calc 2 and all the higher math like that. One of the admissions people sat down with me and saw how frustrated I was. I came and talked to Gary [Masciadrelli] my junior year, and he said, ‘I’ll see you next year.’”

Set to graduate in May, Nawrocki, currently working as an inspector at B&E Tool in Southwick, plans to enroll in the Northwestern advanced manufacturing program, earn his bachelor’s degree, and create more potential landing spots.

Specifically, he’d like to be a project manager or manufacturing engineer. “Something that combines the design side that I like with the practical application of the knowledge,” he explained.

Meanwhile, one his co-workers at B&E, Leah Babinova, a graduate of Westfield Vocational Technical High School last May, is just getting started at STCC.

She was inspired by her two sisters, both of whom went to STCC. One is now working toward a degree in aerospace engineering, while the other is working for a manufacturer in Connecticut.

Also an inspector at B&E, Babinova said she had that job before she even graduated from high school. Surveying the field, she said there are many attractive career opportunities already within her reach, and many more if she adds college degrees.

“There are a lot of good jobs out there,” she told BusinessWest. “Most people just aren’t aware of how many opportunities there are.”

Amanda Cyr is well aware. She’s already been working in the aerospace-engineering field for roughly eight years, since just before her graduation from Westfield Voke.

She’s currently at GKN Aerospace in Newington, Conn. as a manufacturing engineer and robotics programmer. She graduated from the associate-degree program at STCC and is now enrolled in the Northeastern program to generate more of those options her classmate Ryan talked about earlier.

David Nawrocki, an inspector at B&E Tool, is working toward his associates degree, and will press on for his bachelor’s

“I just want to continue growing within the industry and have plans to possibly be in a leadership role,” she explained. “And I think having a bachelor’s will help me down that path.”

She spoke for her classmates, her co-workers, and just about everyone else in the industry when she talked about why she chose it as a career.

“It’s challenging, it’s fast-paced, but it’s good — really good,” she said, while Ryan, sitting next to her, nodded her head in agreement.

“The whole world revolves around manufacturing,” she told BusinessWest. “Everything around you has to be manufactured, so if you think about things in that way, you get engaged in it. And the more you get engaged in it, the more you enjoy it.”

Part and Parcel

As Masciadrelli talked about the manufacturing field and the many types of opportunities within it, he said that, while the money’s good, and that’s important, the work itself brings many different kinds of rewards that are not obvious to many on the outside looking in.

“It’s an exciting field — you’re doing something, you’re making something,” he told BusinessWest. “You start with a drawing, and all of the sudden, that becomes something real; things fit together, or they don’t fit together. That’s what fun about it.”

People like Scott Vovk, Elizabeth Ryan, Amanda Cyr, and Victoria Bradenberg have already figured that part out. The region’s manufacturers need hundreds more to become similarly enlightened if they are to have enough talented people to handle the contracts coming their way.

It’s a huge challenge in every respect, but there is progress being made, in every sense of that phrase.

George O’Brien can be reached at [email protected]