In Its Fifth Decade, OMG Inc. Keeps Growing and Innovating

View from the Top

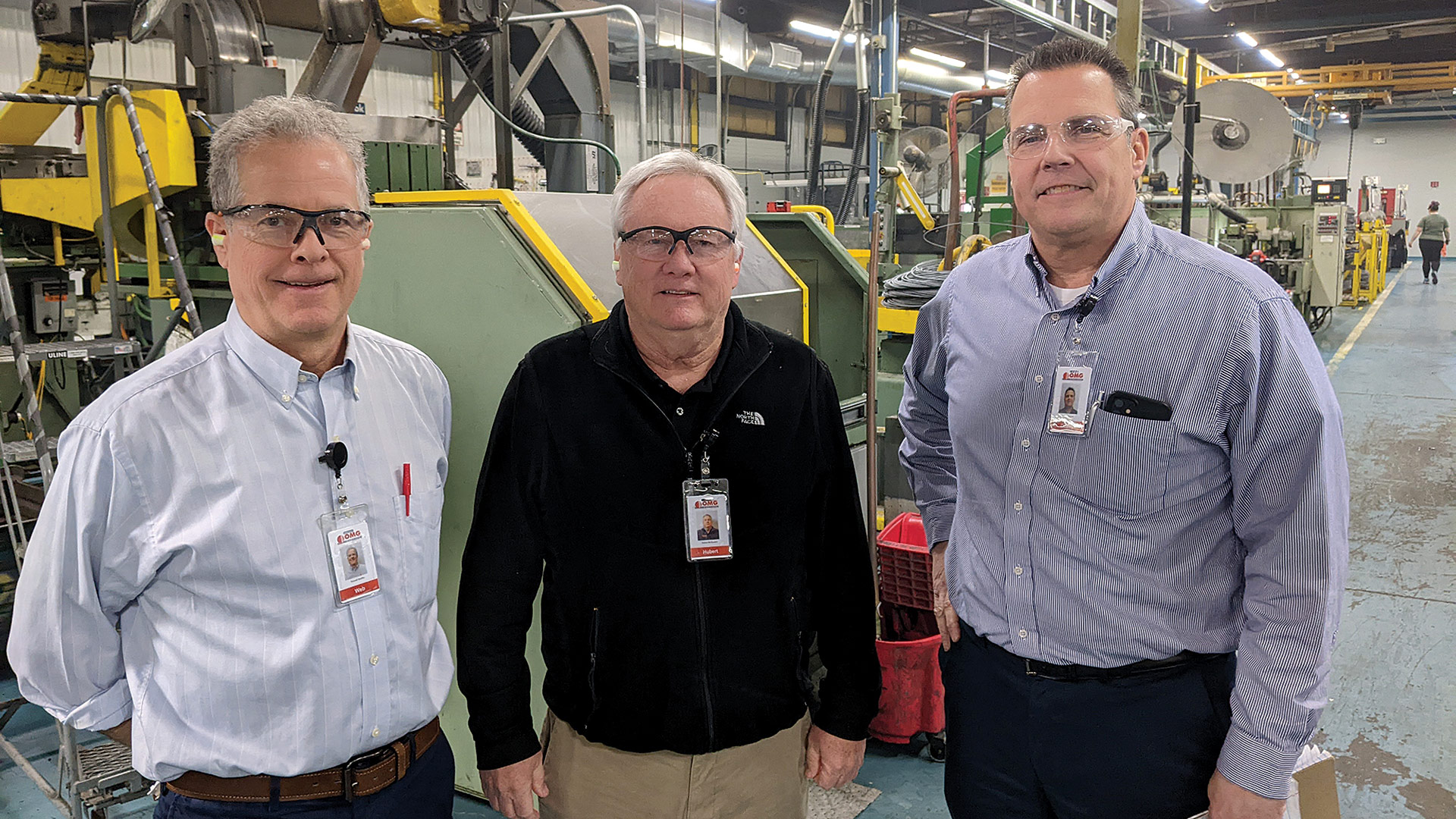

From left, Web Shaffer, Hubert McGovern, and Dewey Kolvek on one of the plant floors at OMG Inc.

The past three years — spanning the pandemic and all the ways it has impacted industry, from supply chains to workforce challenges — have been rough on businesses of all kinds.

But for OMG Inc., it’s been a different story.

“I want to say three-quarters of the business is re-roofing,” said Web Shaffer, senior vice president and general manager of the firm, which encompasses two main divisions: OMG Roofing Products and FastenMaster. “So, while it’s not entirely recession-proof, when your roof goes, you can patch it for a little while, but you can only do that for so long.”

OMG President Hubert McGovern agreed. “You either get a bucket, or you get a new roof.”

And the bucket isn’t the ideal choice for a large company — think of an Tesla factory, a Target store, or an Amazon warehouse — with plenty to protect under that roof.

Meanwhile, 2020 found people stuck at home, not going on vacation, and, in many cases, investing in their homes, said Dewey Kolvek, OMG’s senior vice president of operations. “During the pandemic, it was crazy, with everybody battening down the hatches. A lot of people were at home, looking around, and saying, ‘you know, maybe we should remodel our bathroom. Maybe we should remodel the kitchen. Oh, let’s put a deck out in the back.’”

OMG Roofing Products, which manufactures and supplies roofing fasteners, adhesives, and rooftop drains, pipe supports, and solar mounts, as well as proprietary installation technology for the flat-roofing market; and FastenMaster, which develops fastening and adhesive products used by remodelers, deck builders, residential framers, home builders, and floor installers, both benefited from this environment.

“We’re not making basic drywall screws or something like that. If we have a new product, it’s got to have a feature, a benefit, a patented intellectual property, and something the customer wants.”

And during a time of global supply-chain issues in 2021 and 2022, “we grew out of control, and we couldn’t keep up,” McGovern said. “These last two years have been record years for the company because of the demand. It’s finally starting to settle, but we’ve been under the gun to produce as much as possible, as fast as possible, for probably two and a half years.”

Kolvek recalls it all vividly. “For a period there, we were on 24/7 for two months, just to try to put a dent in it. It was brutal.”

OMG is no stranger to growth spurts. After launching in 1981 as Olympic Fasteners, by 1987 it was manufacturing 100 million fasteners a year. In 1993, the company became Olympic Manufacturing Group — hence the OMG acronym — and in 1997, it was acquired by Handy & Harman, which was later taken over by a public company called Steel Partners. Throughout its history, OMG has grown about 10% a year, on average, through organic growth, constant product development, and a series of acquisitions.

Today, OMG boasts more than 650 employees — about 450 of them at its Agawam campus, which spans 480,000 square feet over a half-dozen buildings — and records about $400 million in annual sales. Its three other plants are located in Addison, Ill., Charlotte, N.C., and Rockford, Minn., in addition to field salespeople located across the U.S. and overseas. The company estimates that around 65% of all commercial, industrial, and institutional buildings in the U.S. that have been built or reroofed within the past 25 years have one or more of its products on their roof.

“The good news about roofing is, people need roofs,” McGovern said. “So if you have a decent building, you’re not willing to let it just deteriorate; you’re going to get a new roof if you need it. Or you’re going to have a lot of buckets and be running around like a chicken with your head cut off every time it rains.”

Hot Stuff

During BusinessWest’s recent visit to OMG’s factory in Agawam, Shaffer pointed out a Chinese advertisement for RhinoBond, the first non-penetrating, induction-based roof-attachment method in North America, which OMG introduced in 1999.

“RhinoBond is a global leader in induction heat welding, and a leading-edge technology in the commercial roofing industry,” he noted. “So we make stuff in Western Mass. and export it to places like China, which is pretty cool. It usually goes the other way.”

McGovern said OMG has a family of about 20 patents on its induction roofing technology, which uses heat to meld the roofing membrane to a fastener plate without having to puncture the membrane with a screw. “It’s a different way of doing roofing — and we lead the market with that.”

On an aerial photo of the Agawam campus, he pointed out a building dedicated to research and development that houses about 30 employees, mainly engineers, who work on developing new products. Over the years, the company’s developments have included TrapEase, the first composite deck screw that does not mushroom; OlyBond Insulation Adhesive, a two-part, low-rise polyurethane foam; OlyBond500 canisters, a new method of applying adhesive, and many more.

This flat roof will use OMG’s patented heat-induction system, which requires no screws to pierce the membrane.

“A lot of the growth has come from looking at our customers and saying, ‘what else can we sell these guys that will help them build a better roof?’” Kolvek said. “And that’s where you see our drains come in, or the solar mounts and other things. Those accessories have helped grow the business, as well as new technologies that cannibalize some of our original product line or allow a more premium solution to builders.”

Shaffer agreed. “We’re really getting out there to the customer and saying, ‘how can we help you? What are your challenges you’re facing?’ And maybe we can bring a solution to the table.”

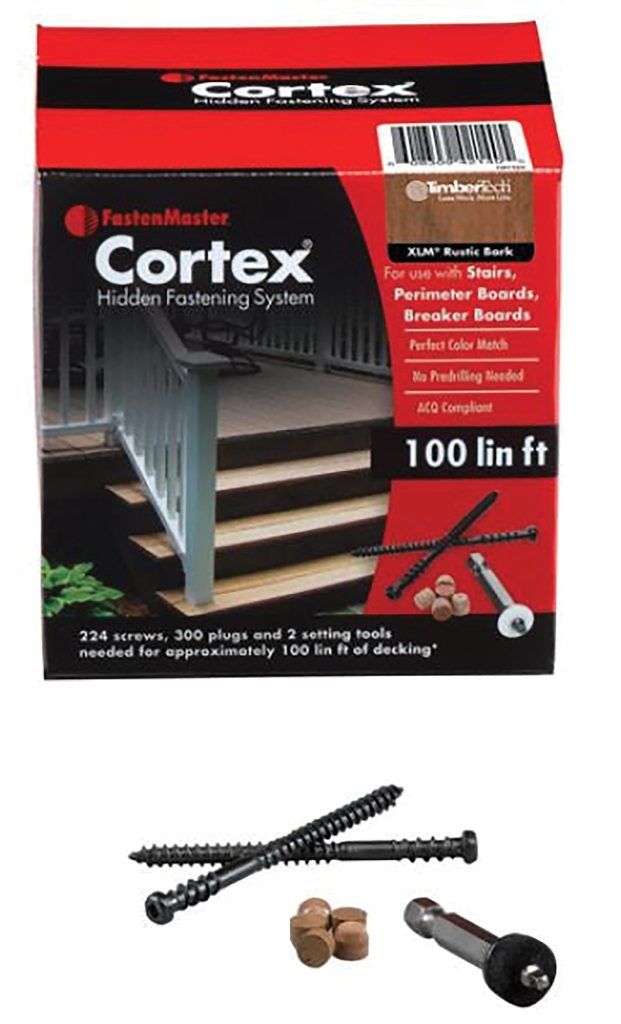

FastenMaster in particular has been introducing new products at a brisk pace, as evidenced by an innovation award it received from Home Depot in November, for its Cortex Hidden Fastening System, which is used to build a deck with fully hidden hardware and fasteners. That kind of continuous development is possible only by staying atop and even spearheading industry trends, McGovern said.

“Some of the technology is changing, but we’ve changed some of the technology with our products,” he noted. “And we’re not making basic drywall screws or something like that. If we have a new product, it’s got to have a feature, a benefit, a patented intellectual property, and something the customer wants.”

“We’re in Western Mass., and we’re all vying for the same pool of workers. So what makes you different than someone else you’re competing against for that same labor?”

Clearly, customers do want them — not only domestically, but in a place like China that’s known much more for its imports to the U.S. than its exports from stateside manufacturers. “You don’t see that a lot in any industry — maybe in some more high-tech ones,” Kolvek said. “But in the construction industry, there’s a lot more imported product. So we have to be different — and better. That’s the bottom line.”

And when OMG develops a successful product, similar products will follow, as with the OlyBond canisters. “We introduced that technology to roofing and, it took off — tens of millions of dollars of sales in a very short period of time,” McGovern said. “Now everybody has a canister technology.”

Last year, Home Depot gave one of its three innovation awards to OMG’s Cortex Hidden Fastening System.

“In business, that’s what happens,” Shaffer added. “If you’re successful like Tesla, well, somebody else is going to come out with electric cars. They’re not going to let you just do that forever. So you’ve got to move on and innovate again, which is what that whole R&D building is all about.”

And being first to market is important when operating on a global scale, McGovern said. “Then it’s everyone else playing catch-up.”

A key element in OMG’s success has been its embrace of lean manufacturing concepts, Kolvek explained.

“We have a pretty robust continuous-improvement program where we want all employees to be engaged with that thought: what is a better way? How do I improve efficiencies? Can I work safer? Can I work faster? You know, really just instilling people to understand the principles of driving the waste out of everything that we do. There’s always an alternative, and we have to pursue that to stay competitive and stay out in front.”

Shaffer agreed. “How do we compete globally from Western Massachusetts, which is not an industrial region? It’s the innovation plus lean operations keeping costs down and improving that value proposition to the end user. Managing costs and innovating — that’s how we succeed here in Western Mass.”

Focus on People

McGovern said the importance of employees is also reflected in initiatives ranging from tuition reimbursement and financial-wellness programs to company picnics, subsidized healthy meals, and physical-wellness programs such as yoga, massage therapy, and a gym and fitness trainer on site.

“These are all things that enhance people’s lives, that aren’t necessarily attached to the working piece of the company. But if people feel better about themselves, if they’re financially well, if they’re physically well, then we know they’re going to be a better employee. We win, and they win.”

Such efforts are even more important at a time when businesses of all sizes struggle to recruit and retain talented workers.

“It’s a huge issue. That’s why we spend a lot of time and money on it,” McGovern said. “We want the best employees, and we want them to stay. And it’s not an easy market.”

The goal has been to create an employee-centric culture, Kolvek added, and the proof of that model’s success is OMG’s continued growth.

“Management will walk the floor every day, in different areas of the company, just to find the pulse: ‘what are your challenges? What can I help you solve? Do you need anything from me?’ Maybe we’ve got to make an investment somewhere, and who better to highlight that than the person who’s dealing with that challenge day in and day out?

In addition, “you have to differentiate yourself from your competition,” Kolvek said. “We’re in Western Mass., and we’re all vying for the same pool of workers. So what makes you different than someone else you’re competing against for that same labor? If you have employee programs where people see value and benefit, they’re going to be more inclined to come here, stay here, and make a career here.”