Current Events

President Jeff Goodless

Early on, Jeff Goodless knew life wasn’t easy in the world of electrical contracting.

But he also knew his family had built a strong reputation in the field since 1945, so it was always on his mind to one day enter the family business.

“I went to Northeastern University for five years,” he said, studying electrical engineering and business management there in the 1970s and taking advantage of NU’s well-known co-op work programs. “Everybody said, ‘why did you go to the co-op school?’ But I wanted to go through the experience of actually working and doing real interviews, knowing I was coming here, just to have that experience.

“I came back here and thought I was going to take a month off, and my father said, ‘you can have a day off,’” he went on. “So I came right to work, right out of college.”

He knew that was a good decision and knows it even more now, almost a half-century later, with Goodless Electric marking 78 years in business, still serving clients in the residential, commercial, and industrial sectors, just like his father, Leon Goodless, and uncle, Irving Goodless, did from the start.

Irving launched the business behind his parents’ home in Springfield, and his brother Leon joined in 1957, when the firm took the name Goodless Brothers Electric Co.

They did quite a bit of moving in the first few decades, Jeff said, to Riverdale Road in West Springfield, Worthington Street and then Winter Street in Springfield, then to the current location at 100 Memorial Ave. in West Springfield, alongside the Route 5 rotary at the Memorial Bridge. Irving retired in 1977, Irving retired in 1977, around the time his nephew came on board part-time. Jeff moved into a full-time role around 1982 and eventually took over the firm’s leadership.

“Everybody went into computer technology. That’s really what happened; they all went into IT, computer technology, and they weren’t going through the electrical programs. But now, I think the classrooms are filling up again.”

“Believe it or not, the type of work has stayed the same, although maybe on a larger scale later,” Jeff told BusinessWest. “But even way back when, they always did residential, industrial, and commercial work. They ran maybe three, four, six guys.”

At its heyday, Goodless said, the company was running about 90 workers, where now, it boasts about 20, keeping them busy with projects ranging from parking-lot maintenance and upgrades, generator services, and fire-alarm systems to lighting retrofits, swimming pools and hot tubs, and residential and commercial service upgrades, just to name a few.

“There’s a lot of jobs with UMass Amherst, a lot of state work, some city work, fire stations, DPW facilities, a little bit of everything. A lot of work for the housing authorities throughout the years, too,” he said. “We don’t do new homes, but I do additions and a lot of repair work. Out of our service department, we run about four vans, and we roll basically 24 hours a day.”

Goodless Electric celebrated its 75th anniversary in 2020, a major milestone for any company.

As the firm celebrated 75 years in business in 2020, an emerging pandemic posed serious challenges, especially since it was performing work at the Holyoke Soldiers’ Home, where COVID killed 84 residents.

“I couldn’t get my people to go up there, and I couldn’t really blame them,” Goodless recalled. “People didn’t want to work; people were scared. I had an outbreak in my office. It was challenging.”

What made a difference, he said, was the federal Paycheck Protection Program, which poured funds into businesses to keep their teams employed. “We took advantage of that; it was so helpful. We used it right. We used it responsibly. We kept guys going. In fact, we didn’t have to let anybody go through the pandemic at all.”

“I tell them, ‘if you work hard, if you work diligently, you can have anything you want. The sky’s the limit if you want to work.”

The economic ripple effects from the pandemic — particularly higher costs and supply-chain issues — still resonate, however. Goodless was able to stock up on things like 100-amp and 200-amp panels to keep housing projects moving, but said customers are still shocked to hear it might take nine to 10 months to get switchgear in.

“We say it over and over again: we’re not the chef; we’re the waiter. We don’t make the stuff,” he said. “It’s still a very difficult message to get through, though.”

The Next Generation

Goodless said the company’s reputation for fast response and competitive bids has helped it earn multiple awards for customer service.

At the same time, though, growth is challenging at a time when building trades of all kinds are beset with a talent drain.

“The workforce situation is awful,” he said. “You can get people, but it’s very hard to get good people in. But I’ve been pretty fortunate; I’ve been able to pick up a few people along the way during the past couple of years, and I’m working on a third one right now.”

Part of the issue has been the pipeline of new, young talent not keeping up with the pace of retirements, but Goodless said that might be changing.

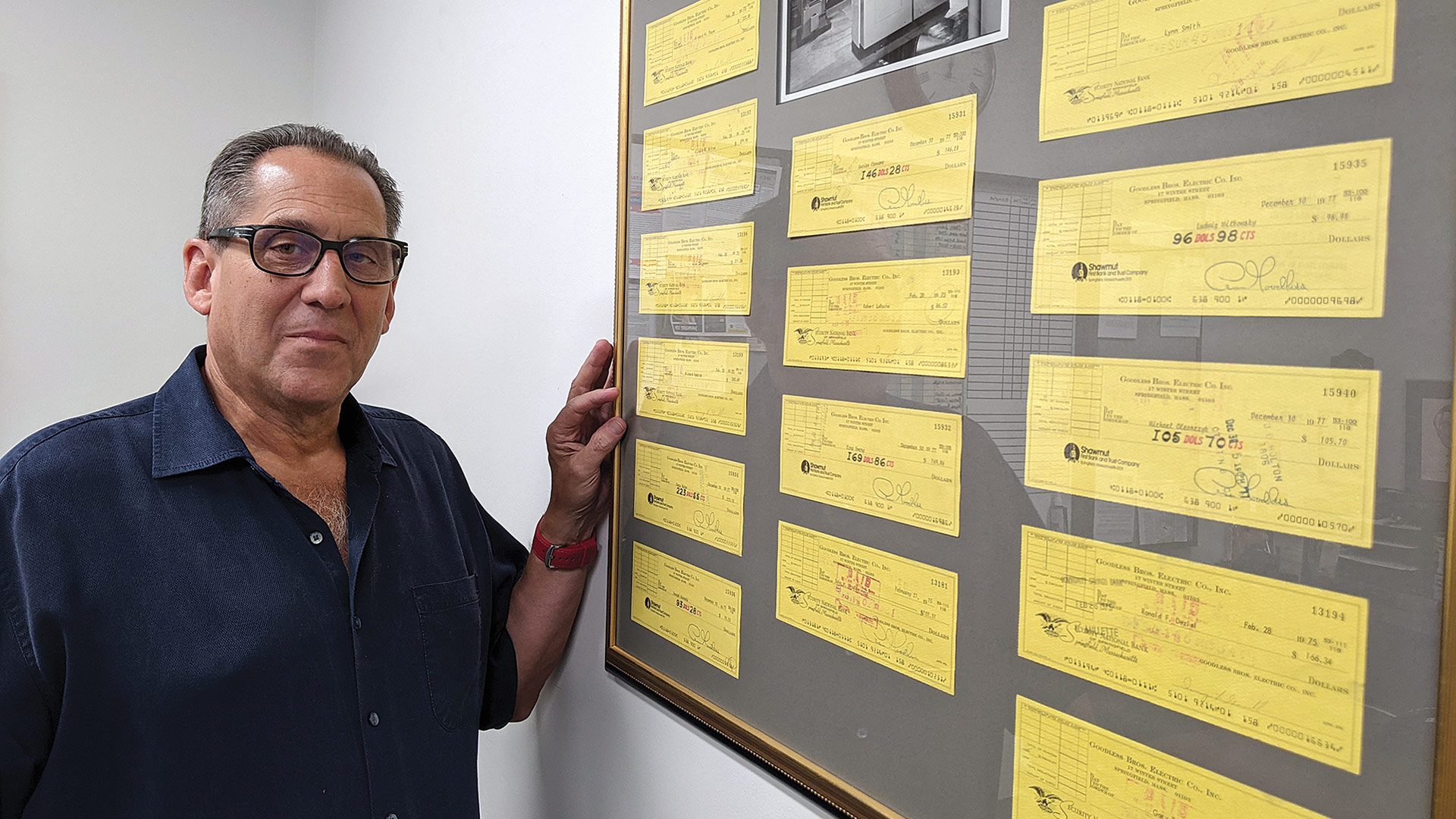

This wall represents some of Jeff Goodless’ first projects for clients in the late ‘70s.

“Over the years, we noticed a huge decline in the electrical trade,” he said, referring to the programs young people were choosing to study. “Everybody went into computer technology. That’s really what happened; they all went into IT, computer technology, and they weren’t going through the electrical programs. But now, I think the classrooms are filling up again.”

He’s gleaned as much through conversations with teachers at the trade schools in Springfield, Westfield, Holyoke, and others, who say students are more serious than before about entering the electrical field and other trades. Part of the reason may be the talk of graduates of four-year colleges entering the workforce with six-figure debt and a cloudy career path.

“A kid in a trade, they’ll pay their dues and go through the program, and at the end, you can make well over 100 grand a year. And you’re going to do your side jobs like everyone does and make another 25 grand,” he said. “I tell them, ‘if you work hard, if you work diligently, you can have anything you want. The sky’s the limit if you want to work.’”

And work hard Goodless has over the past four-plus decades, outlasting many former clients whose companies are no longer in business. And it’s work he relishes.

“Everybody will have something different to say,” he noted when asked what he enjoys about running this 78-year-old business. “I love going after a bid, going over the numbers, and winning the bid. That gives me a thrill. My second-biggest thrill is going out and doing the buys.”

He’s also got his eye on making sure Goodless Electric continues to be a force for many years to come, even after it moves past family ownership.

“I always think about what I’m going to do with this business as I’m getting older. My ultimate goal is to turn it over to the employees, or half to the employees and maybe sell the other half, something of that nature,” he said. “I just want to keep the business going, keep the name going.”