Beyond Four Walls

By Emily Thurlow

The Newman Catholic Center at UMass Amherst is among PDC’s notable recent projects.

One of Nick Shaink’s earliest memories with Professional Drywall Construction Inc. was working as a laborer for the buildout of the Target store at the Holyoke Mall. As a teenager, he worked with the Springfield-based commercial drywall contractor on weekends and on summer breaks.

Now, more than two decades later, the firm is undertaking larger-scale projects, like a 900-room dormitory at the University of Connecticut, and Shaink is co-owner and vice president of PDC Inc.

While the company’s name reflects its origins in drywall, PDC offers services in structural metal framing, finish carpentry, acoustical ceilings, wood framing, plastering, toilet partitions, and more. Most recently, the company landed a job that solely involves installing metal panels on the exterior of a building.

“We’re starting to get work that’s not our traditional scope of work — it’s our expanded scope of work,” co-owner and President Ron Perry said.

Founded in 1994 by John Kendzierski, PDC has been affiliated with the local carpenters’ and laborers’ unions since 1997.

Over the course of Shaink’s career with PDC, he’s held nearly every job — from carpenter and general superintendent to vice president of Operations. A native of Connecticut, he had aspirations of running his own business and eventually relocated to Hampshire County.

Perry, who has been with the company for eight years, was previously a construction manager for two decades. In that prior capacity, he often hired PDC for construction projects, which is how he met Shaink. Over time, Perry learned that they shared similar ambitions. After Shaink approached Perry about going into business together, the pair purchased the company in 2018.

“I’ve always wanted to own a business; that’s always been a dream of mine,” Perry said. “So when this opportunity came up, it was something that I couldn’t pass up.”

Since then, the business has expanded its footprint into Connecticut, opening an office in Norwalk in 2018, and into New York, with an office in Malta in 2021. The multiple locations support each other, Perry said.

While PDC’s Springfield headquarters is handling some of the larger projects, such as the interior framing, insulation, and drywall for UConn’s hockey arena, its Malta location is currently working on a Starbucks at Rivers Casino & Resort Schenectady. For now, the decision remains to take the growth pattern a little slower at the company’s newest office.

“I’ve always wanted to own a business; that’s always been a dream of mine. So when this opportunity came up, it was something that I couldn’t pass up.”

“We want to make sure that we build the right team. We want to make sure that we have the right manpower, instead of taking the giant job out in New York where we could potentially fail,” Perry said. “We’re starting a little slower and trying to grow responsibly there.”

Piecing It Together

Over the years, PDC has built a name for itself in renovation and new, large-scale construction projects for retail, medical, and educational organizations in Massachusetts, Vermont, New Hampshire, and Connecticut. The company also has a bonding capacity of up to $100 million.

Notable structures that PDC has had a hand in include the Bone & Joint Institute at Hartford Hospital, Baystate Medical Center’s Hospital of the Future expansion, Taconic High School in Pittsfield, and Wahconah Regional High School in Dalton.

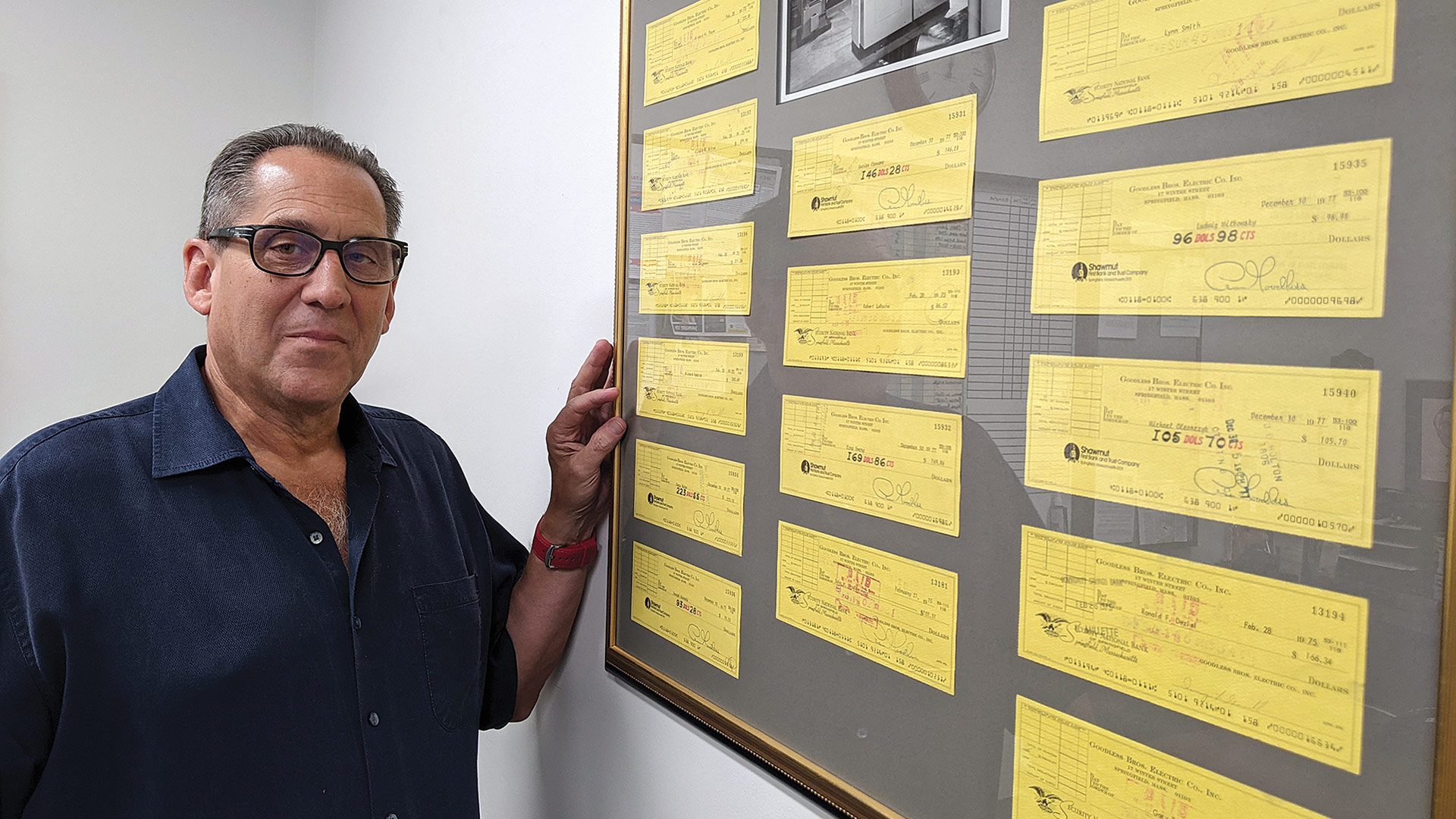

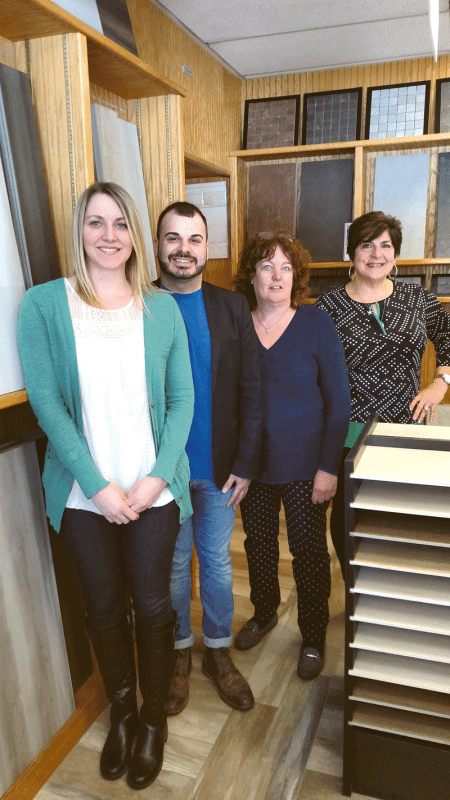

PDC owners Nick Shaink (left) and Ron Perry say they want to keep growing the company gradually and smartly.

The company has also worked on more than 30 projects at UMass Amherst in the last 15 years, Shaink said, from its striking design of Isenberg School of Management to the UMass Design Building and the Newman Catholic Center.

At the campus’s Old Chapel, the company installed pre-fabricated, structural cold-formed metal framing, sheathing, and roof blocking on the building’s exterior, and installed framing walls and drywall on the interior. Workers also installed soffits, which is the underside of part of an architectural structure like an arch.

Work also included the installation of wood stairs, acoustical ceiling tiles, and acoustical plaster systems.

“Our goal is to try to do as many of the things we’re good at under one contract. It gives us more control over costs. It gives us more flexibility … it gives us more work on that job, as contracts are a little bigger,” Perry said. “We’re able to do more work with less — that’s why we want our jobs to be bigger. We want to do a bigger scope of work.”

Drywall — a staple in modern homes and buildings in the U.S., also referred to as wallboard or plasterboard — is made of two paper boards with gypsum, a gray or white soft sulfate mineral, in the middle.

The prototype for the invention was patented by Augustine Sackett in 1894, according to the National Inventors Hall of Fame. However, it wasn’t widely accepted as a building material until the 1940s.

Taking the art of drywall a step further in customization, PDC uses a unique method to mill a perfect corner, called ‘origami.’ Much like the Japanese art of folding objects out of paper, PDC’s approach enables its employees to shape a piece of drywall to fit a space more efficiently at the Springfield shop beforehand. Instead of using three separate pieces of drywall to make a column, they can use one piece of drywall, fold it, and glue it together in the desired angle, then install it in one piece.

By using this method, Perry explained, the drywall is not only a durable solution, but it is also a more efficient one, as the profiles are pre-fabricated in the shop. “It makes our lives in the field less complicated. It’s efficiency in the field.”

And, as with most contractors, time and scheduling are of the utmost importance.

Leveraging Growth

About a decade ago, the annual drop in temperature also meant a drop in projects. But for the past five years, PDC hasn’t really slowed with the changing of the seasons, Perry said. “It doesn’t ever stop.”

In the months leading up to COVID-19, the company secured a number of jobs, which helped carry it through what were some trying times for other organizations. Despite the uncertainty, Shaink said the company’s workload never really slowed down.

Fortunately, even as businesses across all sectors, especially in the construction realm, have battled persistent workforce shortages, labor has not been much of an issue at PDC, as the company continues to fluctuate between 280 and 300 employees.

The main obstacle during the pandemic — and it’s still an issue — is supply-chain issues for materials. The variety of metal studs the company uses for projects has traditionally been available within a week or two. But in the post-pandemic world, those same metal studs are taking up to eight weeks to arrive. That delay impacts the schedule, which in turn impacts the company’s ability to forecast as accurately as it would like.

“When that lead time is eight weeks and you’re buying material that’s eight weeks away, and it comes, and it turns out you don’t have enough — that’s eight more weeks,” Perry said. “And guys standing around is what costs us the most amount of money.”

One of the hardest-to-get products has been insulation. At one point, insulation, which was typically available within a few weeks, took up to nine months to arrive. In an effort to overcome such delays, Perry said PDC purchased multiple truckloads of insulation in advance and then had to find a place to store it all, hoping the job would still come to fruition.

“It’s complicated to forecast,” he said. “It’s a risk of where to put so much money.”

As for future projects, PDC has been awarded the construction of the new Holyoke Veterans Home. The 350,000-square-foot facility will include a chapel, outdoor gardens, and a pavilion for physical and occupational therapy, as well as outdoor events.

PDC will be tackling the interior and exterior framing, installation of medical headwall systems, drywall installation, and finishing. Once completed, the $483 million project will house 234 long-term-care beds for the medically vulnerable veteran population. Work is slated to begin in the fall of 2024.

In the meantime, both Shaink and Perry still have their sights set on growth, and they’re not getting hung up on a particular volume of work, but rather focusing on sustainability.

“We want to grow the business to be as big as we can and as profitable as we can,” Perry said. “I’d rather do a little bit less work, and make the margins that we need to be sustainable, than to try to take on additional risk and maybe not make as much money. We’re finding that balance between growth and profit.”