New Products Give Callaway Plant a Needed Bounce

A New Spin

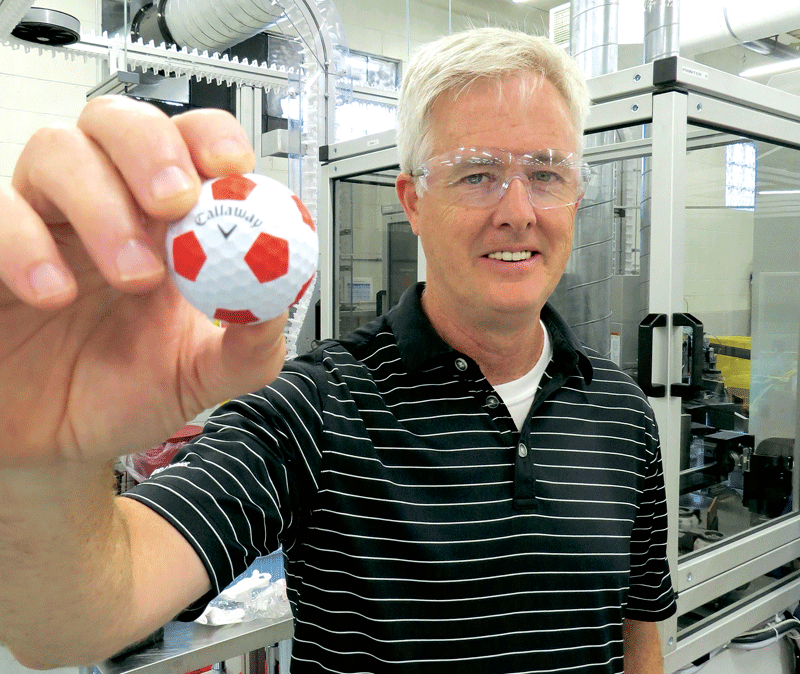

Vince Simonds stands by the Truvis V machine with one of the products of the same name.

Over the past century or so, golf balls — and golf-ball history — have been made in Chicopee. Indeed, the sprawling plant on Meadow Street that once bore the name ‘Spalding’ and now ‘Callaway’ has been home to a number of innovations and new products. In recent years, though, that tradition — not to mention the number of workers at the plant — has been in decline. However, a new and exciting golf-ball design is changing the landscape, in all kinds of ways.

They’re calling it the Truvis V.

That’s the name given to a large, sophisticated piece of machinery recently installed at the sprawling Callaway plant in Chicopee. It was built to carefully place the 12 pentagons that have become the distinctive design pattern for the Truvis golf ball, as well as the Callaway name and the player number, all in accordance with USGA rules and regulations.

This machine is cutting-edge when it comes to such work, said Vince Simonds, senior director of Global Golf Ball Operations for Callaway, adding that it packs as much symbolism as it does science and technology.

Indeed, the Truvis V is perhaps the most visible evidence — except for perhaps the soccer-ball-like product the company has developed — of a compelling turnaround in the history of golf-ball manufacturing in Chicopee.

It’s a long history, to be sure, one that dates back to the late 1800s, but recent chapters have certainly not been as glorious. Decades ago, the talk about this plant was mostly reserved to the tens of millions of golf balls produced there annually. Lately, though, it’s been about the dwindling numbers of men and women working inside; decades ago, more than 1,000 people were employed at the plant, and only a few years ago that number dipped below the century mark.

It’s now at or near 200 and steadily climbing, and there were essentially two catalysts for that growth. The first was the arrival of Chip Brewer as the company’s president and CEO in 2012, a move that energized Callaway in many ways, Simonds noted. The second was the development of the Chrome Soft golf ball, or the “ball that changed the ball,” as the company says in its marketing materials.

This became the ball that essentially changed the fortunes of the Chicopee plant as well, Simonds went on, adding that the product has helped Callaway become the number-two ballmaker in the world (well behind the leader, Titleist), and it has also spurred those growing employment numbers in Chicopee.

The ‘Made in Chicopee’ banner at the Callaway plant has new meaning these days.

And the Truvis model of the Chrome Soft is a very big part of this improved and still-changing picture.

It is still relatively new — it’s been on the market for a few years now — and no one on the PGA Tour is using it yet (more on that later), although Tom Watson is using it on the Champions Tour for players over age 50. But it is certainly catching on among amateurs.

As the name implies, the ball’s claim to fame is that is it is easier to see and enables players to focus better. The product has won some supporters among older players, said Dan Gomez, director of Golf Ball Supply Chain at the Chicopee operation, and among the younger clientele as well, who see is as a break from golf’s staid (some would say stuffy) image.

“It’s something new and different, and some would argue that’s just what’s needed in golf right now,” said Simonds.

The response has been so good that Callaway is having a hard time keeping up with demand. In fact, it isn’t keeping up.

“We’re capacity-constrained right now,”Gomez said with a laugh. “We’ve been sold out on this product for two years; everything we make goes right out — we can’t make enough of them.”

This development explains the Truvis V, but also the fact that space has cleared on the production floor for several more of these machines, and the company plans to add 30 to 40 more workers to operate them.

Indeed, Callaway is quite convinced that the strong interest in the Truvis ball does not represent a fad, like colored golf balls were when first introduced 40 years ago, but rather a business it can build on for years to come. And it is investing heavily in new equipment and plant reconfiguration.

It is also taking very necessary steps to ensure that it will have workers to staff those machines in the years to come. Like all manufacturers, Callaway is having a difficult time finding qualified help, and it is forging (that’s an industry term) relationships with area technical schools to help create a better pipeline.

Part of this relationship building involves tours — officials at Springfield Technical Community College recently visited, for example — designed to impress upon schools and the young people they educate that golf-ball making is alive and well in Chicopee.

And that’s something that really couldn’t have been said just a few years ago.

Round Numbers

Speaking of history, there is quite a bit of it on display, literally, in a row of cases in the hallway leading from the executive offices to the main production floor at the Callaway plant.

There’s more than two centuries of golf-ball technology and product developments behind the glass, including a reproduction of a ‘feathery,’ an 18th-century product that, as the name might suggest, was essentially leather-covered feathers. There’s also some gutta percha balls, or ‘gutties,’ as they were called — products used in the 1800s that were made from dried gum resin from guttiferous trees — as well as dozens of balls from the 20th and 21st centuries with the Spalding name on them, as well as those of several subsidiaries acquired over the years.

There’s even a ball that commemorates the historic moon shot, or moon golf shot, taken by Alan Shepard during the Apollo 14 mission in 1971. (Simonds said there is some ambiguity as to just which brand of ball Shepard used for his famous lunar 6-iron, but he signed a promotional deal with Spalding soon after his return from that mission.)

Dan Gomez, left, and Vince Simonds show off some of the Chrome Soft products that have changed the dynamic at the Chicopee plant.

Further down the hall, there is another display case. Its top rows are currently populated with a number of variations on the Truvis theme — meaning a host of color schemes and a few speciality balls, such as one produced for Australian pro Mark Leishman that has the shape of Australia printed inside the pentagons.

There are rows of empty racks waiting to be filled, as well as the confidence that they will be — something that probably didn’t exist just a few years ago.

Indeed, as he talked about Callaway’s acquisition of Spalding’s assets, including the Chicopee plant, in 2003, Simonds said the ensuing years were certainly not what the leaders at that company hoped they would be.

The company’s consistently sluggish performance in the golf-ball business was coupled with the fact that it was overcapitalized — actually, way overcapitalized — especially with regard to the sprawling Chicopee plant, which was much too big for the company’s needs.

Out of necessity, Callaway downsized and rightsized, said Simonds, adding that it sold the Chicopee plant and is currently leasing back roughly 275,000 square feet, maybe one-quarter the footprint of the original facility.

The rightsizing coincided with Brewer’s arrival as president and CEO of the company and the introduction of new products, especially the Chrome Soft, which is essentially technology that enables lower-compression golf balls to perform as well as higher-compression balls years ago.

These developments led to a dramatic increase in market share — from just over 7% in 2013 to more than 14% at present — which has in turn fueled investments in new product development, and especially the Truvis.

Today, the company is making 200,000 to 250,000 balls a day, and the workforce has steadily grown over the past few years to roughly the 200 mark, about a 50% increase, with more hiring planned, primarily in response to the strong early performance of the Truvis.

“It’s been a phenomenal success,” said Simonds, adding quickly that the company has taken steps, patent-wise (from both a manufacturing and design standpoint), in efforts to protect itself from competitors developing something similar, something he believes they’ll try to do.

At present, there are black pentagons on yellow (popular with fans of the Boston Bruins and Pittsburgh Steelers) and red-on-white options in this country, and a blue-on-white model sold in Japan, he went on, adding that there have been a number of custom orders as well, including green on white for Dick’s Sporting Goods, white on pink for the Susan G. Komen Foundation and Mother’s Day, and red maple leaves to commemorate the 150th anniversary of Canada.

The response has been so strong — those balls shipped to Canada sold out quickly — that Callaway has mapped out an ambitious, three-year capital expansion plan to produce the balls.

The Truvis V, as noted, is merely the first of many that will be installed at the Chicopee plant.

And this is very specialized, and expensive, equipment.

“This is an involved process,” Simonds explained. “When you think about stamping such a large design on a spherical object … you have to distort the artwork so that it doesn’t look distorted on the ball. And we’ve developed some techniques to purposefully and mathematically distort the artwork so that, when it’s placed on the ball, it looks normal.”

Another challenge will be finding qualified individuals to operate these machines, he said, adding that this is why the company is reaching out to STCC and the technical high schools in the area, with the goal of establishing relationships and putting Callaway back on the radar screen for young people looking for career opportunities.

In the meantime, Callaway officials look forward to the day — and they predict it will come — when a PGA tour regular starts playing the Truvis, a development that would give the ball a huge boost in terms of both exposure and credibility.

“Most of the tour pros have them, and they use them for chipping and practicing,” Simonds explained. “But most PGA tour pros are too traditionalist to put those in play. But I think it will happen someday.”

Growth Patterns

There’s another item of interest on the shop floor to the administrative offices at the Callaway plant.

It’s a large banner hanging from a utility duct that features images of the Chrome Soft ball, with the Truvis product well-represented. Above those images, in large white letters, are the words ‘Made in Chicopee, MA.’

Such banners and such words have been seen at the plant for decades, obviously, but today, there is more meaning behind them, more optimism, and more promise, if you will.

A plant that has made a good deal of golf balls — and a great deal of golf-ball history — is entering a new era in which it will produce more of both.

George O’Brien can be reached at [email protected]