Appetite for Growth

The Dennis Group Becomes a Leader in Food Engineering

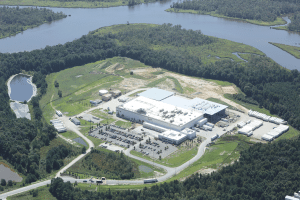

The 120,000-square-foot Sabra hummus plant near Richmond, Va., which the Dennis Group built in 2009, will double in size by 2014.

Well, sort of.

The black-and-white image, affectionately titled ‘The Geeks’ by staff at the Dennis Group, presents what looks like three college students eating hamburgers, with some accompanying verbiage: “we were fascinated by food even before we become engineers.”

It all makes sense — if one is familiar with the company and the niche it has successfully cultivated over the past quarter-century. This would the field known simply as ‘food engineering,’ although that phrase is somewhat of a misnomer and certainly needs some clarification, said Dan McCreary, one of the firm’s four partners.

The company doesn’t actually engineer food, he noted, adding that it designs and builds specialized plants that process many of the convenience-based foods consumers buy every day, from prepackaged lettuce to energy drinks to frozen, ready-to-heat sandwiches.

“We’re actually architects and process engineers for the food industry,” McCreary went on, acknowledging that the latter term itself requires explanation.

And he provided one, noting that there is an elaborate process involved with building such facilities — from selection of a location (more on that later) to operations to energy efficiency, a subject of increasing importance as fuel costs rise and the desire to be ‘green’ increases.

By excelling in the art and science of helping clients navigate this process, the Dennis Group has witnessed explosive growth since it was launched by founder Tom Dennis in his attic. It now boasts nearly 200 employees in its Springfield headquarters (now spaced over four of the renovated Fuller Block’s five floors) and another 100 in satellite offices strategically located in Salt Lake City, San Diego, Toronto, and Atlanta.

Meanwhile, the client list has grown to include many of the household names from the food industry — Nestle, Dole, Tropicana, PepsiCo, and numerous others — and the Dennis Group now books projects totaling more than $500 million annually.

Some of this success can be traced to timing — specifically, an explosion in the popularity of convenience-based foods and the almost (that’s almost) recession-proof nature of the food industry, said McCreary, noting that “people have to eat.”

But beyond these realities, the firm’s remarkable growth can be traced to its relationship-building abilities — it has drawn repeat business from many clients as they have grown and expanded into new business opportunities — as well as an operating philosophy based on calculated risk taking and what often would be considered unorthodox thinking.

As one example, McCreary, who spoke for the company while Dennis was attending to business at one of the satellite offices, cited some aggressive action during the recent economic downturn.

At the height of the Great Recession, two of the firm’s $100 million projects were essentially halted, he noted, but Dennis’ response was not to trim staff and hunker down, but rather hire some of the the talent that was becoming available.

“He said, ‘we’ve often struggled to find the right people when the economy was good, and now, with the engineering, architectural, and construction industry being hit so hard, there’s talent out there,’” McCreary recalled. “So we went on a hiring spree.”

The bold move paid off for the company, he went on, because it was well-positioned to seize the opportunities that came about as economic conditions improved — and it did, adding a number of projects to the portfolio.

For this issue and its focus on environment and engineering, BusinessWest takes an indepth look at the Dennis Group, its appetite for growth, and its status as a true leader in the large and still-expanding realm of food engineering.

Salad Days

They’re called Uncrustables.

That’s the name Smucker’s has put on a simple yet fascinating product — a frozen, ready-to-eat peanut butter and jelly sandwich, one that comes, as that name suggests, without the crust.

“It’s every kid’s dream — they stamp out the center of the sandwich so there’s no crust,” said Tony Graves, another senior partner at the Dennis Group, noting that Smucker’s reached out to the Dennis Group to design and build what eventually became the largest automated bakery in the world, in Scottsville, Ky., to produce Uncrustables.

Smucker’s addition to the supermarket’s frozen-foods aisle is just one example of the direction the nation — and the food industry that serves it — is taking, said Graves and McCreary, noting that there is ever-greater demand for convenience products, including some that probably couldn’t have been imagined a decade or two ago.

Like packaged salad.

“It’s the simplest ideas that are amazing,” said McCreary, who was vice president of Finance for Dole when it ventured into the packaged-salad business more than 20 years ago. “I mean, how hard is it to make a salad? Who is going to buy this? But, as it turned out, everyone did.”

And this phenomenon is one of the many reasons why the Dennis Group has enjoyed steady growth for the past 26 years, said McCreary, who hired the firm (then with 20 employees) to expand Dole’s facilities in California to accommodate the new product lines, and then was recruited by Tom Dennis to join him in his growing venture.

McCreary said he was attracted to the Springfield-based firm by everything from its already-established reputation for excellence to its decidedly different operating philosophy, or culture.

McCreary described the style as “informal,” and as an example, he referred to his business card, which lists only his name and contact information.

“We don’t have titles … we have very little in terms of a management structure,” he explained. “We have 300 people, but we don’t have an employee handbook — not because we forgot or it’s too hard, but because we want people to use their own judgment.

“Our philosophy is that we hire bright, ambitious people,” he went on, “and if we trust an employee to handle millions of our clients’ dollars, then we trust them to know what a sick day is.”

But what ultimately attracted McCreary to the Dennis Group was its vast growth potential, which he recognized while the firm handled Dole’s expansion efforts.

Taking such a facility from the drawing board to reality is a lengthy, complicated process (there’s that word again), he went on, adding that the Dennis Group ultimately owes its sweeping success to its ability to effectively guide clients through the many steps involved.

The Complete Package

The firm’s full menu of services includes everything from design to construction management; from identifying and handling environmental concerns to waste disposal and energy consumption, he told BusinessWest, adding that the process usually begins with the all-important questions of what to build and, perhaps more important, where.

Indeed, geography is a key consideration in the food-production industry, McCreary and Graves explained, adding that location has an impact on everything from energy costs to distribution.

“With these large companies, if you’re trying to distribute a product nationwide, you want to be more toward the center of the country, rather than up in the corner in some cases,” McCreary said, pointing in the air to the Western Mass. region.

“The process begins with questions like, ‘where do your raw materials come from?’ ‘where do you distribute the product?’ and ‘where is the most beneficial location to meet those needs?’” he continued, adding that, once a preferred geographic region is identified, the Dennis Group works with the client to select a specific location.

And there are a number of factors that go into picking a site — from cost and availability of power (food-processing plants consume huge amounts of energy) to the ability of a given community to handle the large waste streams such plants generate.

“A lot of what we solve with a simple checklist of site needs is an educated guess for what the building size will be and how it can be laid out on the site,” said Graves. “It’s what we try to accomplish before the client makes a mistake.”

Ten sites that might be favorable for new building, he added, will quickly turn into only two sites, due to the complexity of the food-production processes and distribution needs.

With assistance on the economic-development side for regional tax-incentive financing, grants for employee training, etc., the Dennis Group is able to identify and design a purpose-built structure around a customized site, and provide construction management for production of a variety of foods and beverages.

In food engineering, as in most business sectors, success breeds more success, said Graves, who has been with the company for 21 years. He said the food industry, while large in terms of dollars, is much smaller in terms of players and the individuals managing them. In this environment, a good track record can help foster relationships that bring new additions to the portfolio.

“You run into the same people year in and year out,” he explained. “They move around within the industry and bring us along with them.”

One example of such relationship-building is the Sabra hummus company. The Dennis Group started working with it in 2009, when it was a $40 million enterprise that wanted to go national. Currently, the firm is leading a project that will double the size of a 120,000-square-foot plant for what is now a $500 million company.

While repeat business is a leading contributor to the firm’s continued growth, the need within the food industry to reduce energy consumption and retrofit aging plants so they are more efficient has also become a source of new business.

“In food, it’s ‘heat things up, cool things down,’ and you’re always cleaning things in these plants,” said Graves. “So that’s where all their energy usage is, and sometimes energy costs more than the raw materials.”

One of the firm’s recent projects, the Frito-Lay Sun Chips plant in Casa Grande, Arizona, is a net-zero facility, meaning that it has annual zero net energy consumption and zero carbon emissions; its energy is supplied by solar-powered facilities.

Food for Thought

Looking ahead, McCreary and Graves said the Dennis Group is well-positioned for continued growth in a number of respects, from those aforementioned relationships within the food industry to simple geography, especially in the form of its satellite offices in Salt Lake City and Atlanta, areas clients are increasingly targeting for new building and expansion.

Meanwhile, the nation’s consumers have a seemingly unlimited appetite for convenience food, and an imaginative and resourceful food industry continues to find new and different ways to meet that demand.

These trends and developments bode well for a company that has always had designs on being a business leader — in every sense of that phrase.

Those who don’t know the story of the Dennis Group probably won’t understand the relevance of that poster in the Fuller Block stairway.

Elizabeth Taras can be reached at [email protected]