Energy for Change

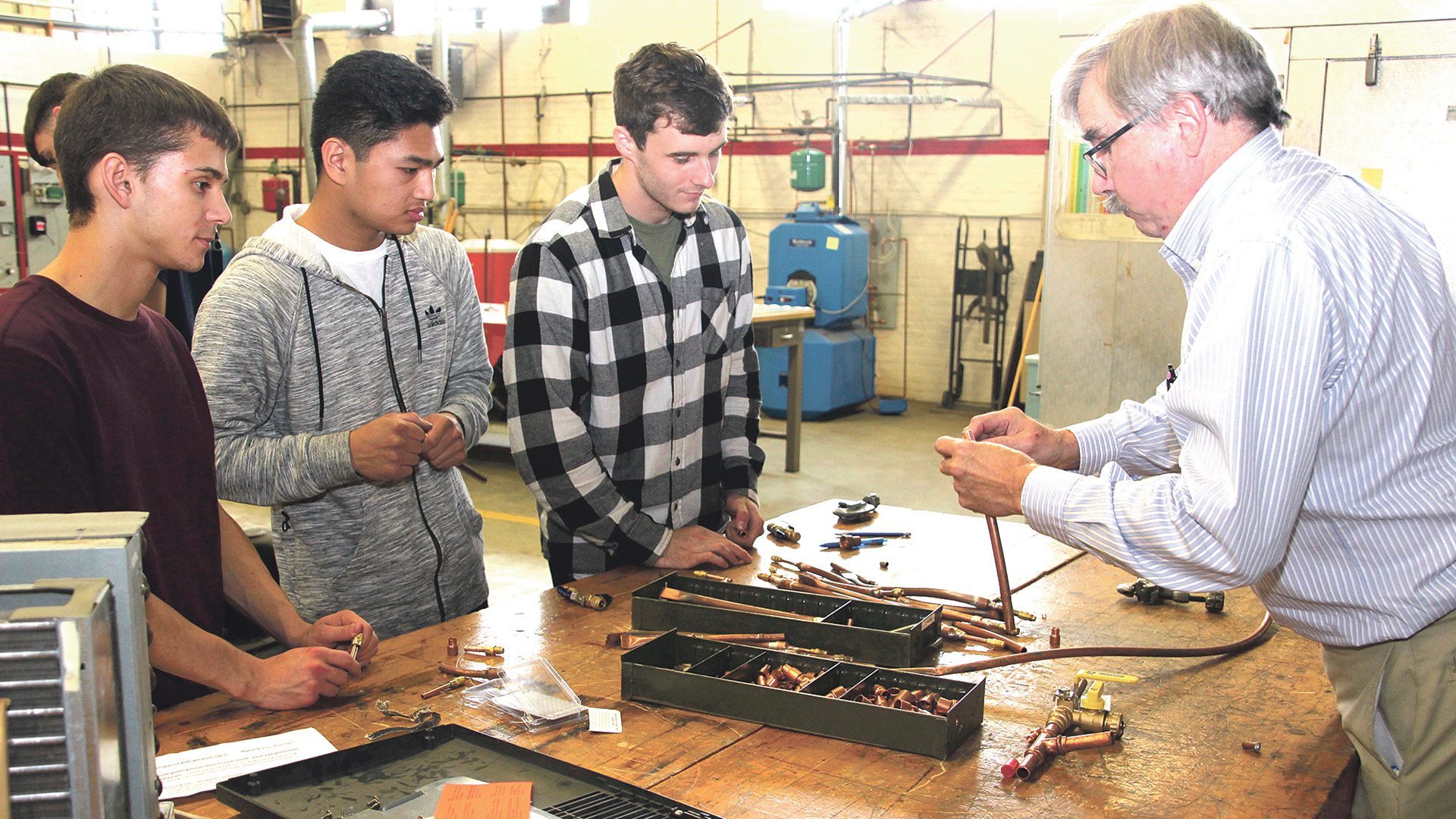

Professor William Halloran teaches HVAC students at STCC.

Dr. Fahad Khan said the HVAC program at Springfield Technical Community College (STCC) has been around since the 1960s.

“Many in the field around here went to STCC at some point,” said Khan, a professor in the college’s Engineering department. “It’s a legacy program.”

It’s also a program that has seen plenty of change and evolution over the years — which has only accelerated in the past decade or so.

Take, for example, an associate degree added in 2019 that focuses on building automation and control systems. Or advances in fuel, such as the emergence of biodiesel.

“Things have evolved a lot since the 1970s; boilers have improved in efficiency,” Khan said. “We still have to use combustion; some people hope that, in the next 10 years, we won’t need to use combustion for heat, but that’s probably too optimistic.”

But changes are already emerging, said Scott Cernak, owner of Western Mass Heating, Cooling & Plumbing in Haydenville.

“The big change in the past few years is the initiative to convert people from fossil fuels to heat-pump technology, or anything electric-driven.”

“The big change in the past few years is the initiative to convert people from fossil fuels to heat-pump technology, or anything electric-driven,” Cernak said, citing a broad push among government leaders in Massachusetts to move toward decarbonization through climate-technology investments and programs like Mass Save.

“People who have the money and care about the environment enough to do it are going to heat pumps — whole-house conversions, partial conversions, a lot of it driven by Mass Save rebates and tax incentives as well. It’s been about a decade-long push, but especially strong over the last two to three years.”

A heat-pump conversion can cost to to three times more up front than replacing one fossil-fuel system with another, he noted, which is why those rebates and incentives are so critical. And the Mass Save program recently committed to a three-year plan in which rebates will not decrease.

“There’s been a lot of training for our sales and estimation staff, manufacturer trainings, climate-initiative trainings from Mass Save,” Cernak added.

In addition, “it’s been a different mindset for people heating their homes. With fossil fuels, it’s very easy to make heat, it’s very efficient, and people feel that warmth right away. Heat pumps are different. You’re harnessing electricity through the heat-pump system, and the heat isn’t as profound as the fossil-fuel heat. So there’s a level of adjustment for the homeowner. And you also need to make sure the house has good-enough infrastructure to support it.”

Scott Cernak says a focus on indoor air quality and a move away from carbonization (in the case of heat pumps) are two major ongoing trends in the HVAC world.

While heat pumps have replaced carbon fuels in many residential and commercial systems, Khan said, the efficiency remains a work in progress.

“They have improved in terms of coefficient of performance, with how much heat you can extract from the outside to the inside. That varies depending on the temperature outside,” he added, explaining that, at very low temperatures, heating costs can rise dramatically. “With heat pumps, you can end up paying a lot of money between December and February.”

One way to combat that, he added, is with water-to-air geothermal heat-pump systems that draw on the stable temperature of the earth’s ground or water sources to provide efficient heating and cooling.

The other big shift in the HVAC world in recent years has been an emphasis on indoor air quality, which was certainly accelerated during the COVID years, but had taken root even before then, Cernak said.

“Indoor air quality has become a focal point in our business as well. A lot of people with allergies and sensitivities have embraced air scrubbers or electronic air cleaners because of all the ancillary benefits. They do kill bacteria and viruses, such as coronavirus. It won’t prevent you from getting sick out in the wild, but it can help you in your own home.”

“These guys are not going to be outsourced anytime soon. You’re not going to see a robot come into the house; somebody has to do the work. An engineer can be outsourced, but who’s going to install and cut metal and lay down the ductwork and do the wiring? Somebody has to do it.”

While technologies continue to advance, Khan said, the state is also focusing on incentives for weatherizing houses, making them more efficient in terms of heat loss and gain. “We’ll still rely on combustion, at least for the next 10 years.”

Priming the Pipeline

With business split about 75% residential and 25% commercial and industrial, Western Mass Heating, Cooling & Plumbing handles all aspects of that name, from installation and retrofitting to new construction and service, Cernak said. “We’ve had a steady incline since our inception in 2020 — we’ve tripled our sales and doubled our workforce.”

That employee growth is impressive in itself, at a time when all building trades are struggling with retention as retirements outpace new talent in the pipeline.

“We’ve seen challenges, especially at first. But we have a strong training program,” Cernak said. “It’s been relatively easy to hire young talent coming up from the trades. They’re not ready to run their own jobs yet, so we’re training them extensively to bring them up into our workforce. The growth has to come from within.

“For a young kid coming out of high school or college, bringing them up to speed usually takes one to three years, depending on the position,” he explained, adding that internal training has been very effective in bolstering his workforce.

Fahad Khan says STCC is equipping students to take the first steps into an HVAC field that needs young talent.

Cernak said the question of whether to go to a four-year college or enter a training program in the trades is one each young person needs to make based on their interests and needs.

“But what I can offer is, we pay for training, and you start making money immediately. Even in an internship, you’re making a livable wage, and then there are frequent increases, good benefits, and it’s satisfying at the end of the day, knowing that, by providing heating or cooling or plumbing, you’re providing comfort, safety, and efficiency in someone’s home.”

Khan also recognizes the need to bring more young talent into the world of HVAC.

“There is a vacuum in this field, as a lot of folks are retiring, or have taken early retirement since COVID. We’re trying to fill the gap.”

While STCC also offers a two-year degree program in HVAC, he explained, the one-year certificate program starts with the basics, and “by the time you finish, you’ve gotten your feet wet. You’ll still require some in-field training; you’re not going to hit the road and start fixing stuff. You’ll want to shadow somebody. But we have a lot of success covering all the bases, so, by the end of the year, you can start training in an internship.”

It helps, he said, that the state offers funding for businesses to take on interns for six months.

“It helps the employer, so they don’t have to carry the burden of training somebody and paying them, and it also helps the students with training hours, and gives them a chance to see if they really want to do it or not.”

Many do, of course, and the pay is a factor; HVAC professionals can make $55,000 after a year, or up to $75,000 or more if they go into automation and control, Khan said.

“These guys are not going to be outsourced anytime soon. You’re not going to see a robot come into the house; somebody has to do the work. An engineer can be outsourced, but who’s going to install and cut metal and lay down the ductwork and do the wiring? Somebody has to do it.

“So it’s a good area to be in, with a lot of job security, and it’s not going anywhere soon,” he added. “We can diagnose things faster, make things more efficient, but in the end, somebody’s got to go into the house for the actual repair.”

Changing Environment

The statewide push toward climate and energy innovation aren’t slowing down, and will continue to impact the worlds of construction and HVAC.

In a speech last month to the New England Council, Gov. Maura Healey cited figures from a UMass Donahue Institute report suggesting that the $1.3 billion her administration wants to invest in climate technology over 10 years would result in $16.4 billion in new economic activity and as many as 7,000 new jobs.

The state spending figure includes $400 million in bond authorizations for capital projects, $300 million in tax incentives, and $300 million to support the Massachusetts Clean Energy Center’s operations, as well as an expansion in eligibility for existing offshore wind tax credits that could cost up to $350 million.

At the same time, the Center for EcoTechnology in Florence — which has been at the forefront of innovation when it comes to energy efficiency and climate impacts for almost a half-century — expects to dramatically expand its work, President and CEO Ashley Muspratt recently told BusinessWest.

“The work we do ultimately rolls up to reducing carbon emissions and shepherding in all of the benefits that come with that,” she said. “Carbon reduction can allow for a better lifestyle in terms of cost savings, health benefits, energy independence, and a more comfortable, better livelihood. We could be tackling this crisis while also paving the way to a better way of life.”

And where there’s a will, innovation will follow.

“The technology is advancing tremendously. It has been forever, but especially the past few years. And that trajectory will probably continue as manufacturers learn new technologies to heat and cool homes efficiently,” Cernak said. “The next change is a new refrigerant which is more environmentally friendly and has a wider range of capability. By 2025, every manufacturer will be affected by that.

“It’s ever-moving,” he added. “We have administrative staff people who are always keeping up with regulations and changes and Mass Save incentives and tax incentives and manufacturer trainings. There are a lot of moving parts, but it all makes it better for the consumer.”